When it comes to commercial ice machine repair in Pasadena, CA, Same Day Appliance Repair is your go-to service provider. We understand how crucial a functioning ice machine is for your business, whether you run a restaurant, hotel, or any other commercial establishment. That's why we offer prompt and reliable repair services to ensure minimal disruption to your operations. Our experienced technicians are well-versed in diagnosing and fixing a wide range of issues, from mechanical failures to electrical malfunctions, ensuring that your ice machine is back up and running in no time.

At Same Day Appliance Repair, we believe in transparent and competitive pricing. Our service call fee starts at just $99, which includes a comprehensive diagnostic of your ice machine. Once the issue has been identified, our technicians will provide you with a detailed estimate before proceeding with any repairs. Labor costs typically range from $75 to $150 per hour, depending on the complexity of the repair. Additionally, any required parts will be billed at competitive rates, and we strive to source high-quality, OEM parts to ensure longevity and performance of your ice machine. For reliable and affordable commercial ice machine repair in Pasadena, CA, look no further than Same Day Appliance Repair.

Cube Ice Machines

Cube ice machines are a staple in many commercial settings, from restaurants to hotels, due to their versatility and the high-quality ice they produce. These machines can generate standard, half, and full-size ice cubes, making them suitable for a variety of applications. However, they also come with their own set of repair needs. Common issues include clogged water filters, malfunctioning thermostats, and ice jams, which can disrupt the machine's operation and reduce its efficiency. Additionally, the condenser coils and evaporator plates require regular cleaning to prevent ice buildup and ensure optimal performance. At Same Day Appliance Repair, our technicians are skilled in diagnosing and repairing all types of problems related to cube ice machines, ensuring your equipment remains in top working condition.

Flake Ice Machines

Flake ice machines are commonly used in industries like seafood markets, grocery stores, and healthcare facilities where soft, moldable ice is preferred. These machines produce small, thin flakes of ice that can easily be shaped around products, providing excellent cooling without damaging delicate items. Despite their utility, flake ice machines can experience issues such as worn-out augers, motor failures, and water leakage. The intricate design of these machines requires specialized knowledge to repair and maintain. Our team at Same Day Appliance Repair is experienced in handling the unique challenges posed by flake ice machines, ensuring timely and effective repairs that minimize downtime and keep your operations running smoothly.

Nugget Ice Machines

Nugget ice machines are popular in settings like fast-food restaurants and healthcare facilities due to the chewable, soft texture of the ice they produce. Known for their high production rates and energy efficiency, these machines are often in constant use. Common repair needs for nugget ice machines include issues with the gear motor, water inlet valves, and ice extrusion mechanisms. Regular maintenance is crucial to prevent scale buildup and ensure the machine operates efficiently. At Same Day Appliance Repair, we understand the importance of keeping your nugget ice machine in peak condition. Our technicians are adept at troubleshooting and fixing a wide range of issues, ensuring you have a steady supply of high-quality nugget ice.

Gourmet Ice Machines

Gourmet ice machines are designed to produce crystal-clear, high-quality ice that melts slowly, making them ideal for upscale bars, restaurants, and hotels. These machines often produce uniquely shaped ice, such as spheres or large cubes, which can enhance the presentation of premium beverages. Due to their specialized nature, gourmet ice machines can face unique challenges, such as issues with the water filtration system, freezing cycles, and mold formation. Regular descaling and cleaning are essential to maintain the clarity and quality of the ice. Same Day Appliance Repair offer s expert services to address the specific repair needs of gourmet ice machines, ensuring that they continue to produce the exceptional ice your business relies on.

1. Insufficient Ice Production:

One of the most common issues with ice machines is insufficient ice production, where the machine fails to produce enough ice to meet demand. This problem can stem from a variety of causes, including a clogged water filter, low water pressure, or a malfunctioning water inlet valve. Additionally, environmental factors like high ambient temperatures or poor ventilation around the machine can hinder its efficiency. Regular maintenance, such as cleaning the condenser coils and replacing water filters, can often mitigate these issues and ensure optimal ice production.

2. Ice Machine Not Making Ice:

When an ice machine stops making ice altogether, it can be a significant disruption, especially in commercial settings. This issue can be caused by several factors, including electrical problems, a faulty thermostat, or issues with the water supply. For instance, if the water line is kinked or frozen, the machine can't get the water it needs to make ice. Electrical issues might involve a blown fuse or a tripped circuit breaker. Diagnosing the exact cause typically requires a thorough inspection and, in some cases, professional repair services.

3. Poor Ice Quality:

Poor ice quality, such as cloudy, misshapen, or foul-tasting ice, is another frequent issue. This can be due to impurities in the water supply, a dirty water filter, or mold and mildew buildup inside the machine. If the water filter is not changed regularly, it can no longer effectively remove contaminants, leading to subpar ice. Additionally, if the machine is not cleaned and sanitized on a regular schedule, bacteria and mold can grow, further deteriorating the ice quality. Ensuring a clean water supply and maintaining a rigorous cleaning schedule can help address these problems.

4. Ice Machine Leaks:

Leaks are a common problem that can result from a variety of issues within the ice machine. Leaks can occur due to a cracked or damaged water line, a faulty water inlet valve, or a clogged drainage system. Over time, the wear and tear on these components can lead to small fissures or blockages that cause water to escape. It's essential to identify the source of the leak promptly to prevent water damage and maintain the machine's efficiency. Regular inspection of hoses, valves, and connections can help catch potential leak sources early.

5. Strange Noises:

Strange noises emanating from an ice machine can be indicative of several underlying problems. These noises may include grinding, buzzing, or clicking sounds, each pointing to different issues. Grinding noises often suggest a problem with the motor or the auger, while buzzing sounds could indicate electrical issues or a failing compressor. Clicking noises might be related to the ice maker's harvest cycle or issues with the solenoid valve. Investigating and identifying the noise source is crucial, as leaving these issues unresolved can lead to more severe damage or complete machine failure.

6. Ice Machine Freezing Up:

When an ice machine freezes up, it typically means that there is excessive ice buildup within the unit, which prevents it from functioning correctly. This can be caused by a malfunctioning thermostat, improper temperature settings, or issues with the defrost cycle. Additionally, if the machine's evaporator fan is not working correctly, it can lead to uneven cooling and ice buildup. Regularly checking and calibrating the machine's temperature settings, as well as ensuring that all components are working correctly, can help prevent freeze-ups and keep the ice machine running smoothly.

7. Electrical Problems:

Electrical issues can manifest in various ways, such as the machine not powering on, intermittent operation, or tripping circuit breakers. These problems can be caused by faulty wiring, worn-out control boards, or issues with the power supply. Ensuring that the machine is connected to a dedicated electrical circuit can help prevent overloads. Regular inspections by a qualified technician can identify and address potential electrical problems before they cause significant disruptions or damage to the machine.

1. Water Inlet Valve:

The water inlet valve is crucial in regulating the flow of water into the ice machine. This electrically-controlled valve opens and closes to allow water to enter the ice maker's reservoir. If the valve is faulty or clogged, it can lead to insufficient water supply, resulting in poor ice production or no ice at all. Replacing a malfunctioning water inlet valve is essential to restore the machine's proper functionality. Regular inspection and cleaning can prevent debris from causing blockages, ensuring consistent water flow for ice production.

2. Water Filter:

A water filter in a commercial ice machine is designed to remove impurities, contaminants, and particulates from the water supply, ensuring the production of clear, high-quality ice. Over time, water filters can become clogged with sediments and minerals, reducing their effectiveness and potentially compromising the taste and appearance of the ice. Regular replacement of the water filter is necessary to maintain the quality of ice and to protect the machine's internal components from scale buildup and damage.

3. Thermostat:

The thermostat in an ice machine monitors and regulates the internal temperature to ensure optimal ice production. A malfunctioning thermostat can lead to improper temperature control, resulting in either inadequate freezing or excessive ice buildup. This can disrupt the ice production cycle and affect the machine's efficiency. Replacing a faulty thermostat is crucial to maintaining the correct operating temperature and ensuring the consistent production of ice. Regular calibration and testing can help identify issues early.

4. Condenser Coil:

Condenser coils are responsible for dissipating heat from the refrigerant, allowing it to cool and cycle through the system effectively. Dirty or clogged condenser coils can hinder heat transfer, leading to reduced ice production and increased energy consumption. Regular cleaning of the condenser coils is essential to maintain the ice machine's efficiency and prevent overheating. In some cases, damaged coils may need to be replaced to restore proper function and ensure optimal cooling performance.

5. Evaporator Plate:

The evaporator plate is where the actual freezing of water occurs to form ice. Water flows over this plate, and as it cools, it freezes and forms ice cubes or flakes. If the evaporator plate becomes damaged or develops issues such as scaling or corrosion, it can hinder the freezing process, leading to irregular ice formation or reduced ice production. Regular cleaning and descaling of the evaporator plate are necessary to maintain its efficiency. In cases of severe damage, replacing the evaporator plate may be required to ensure consistent ice production.

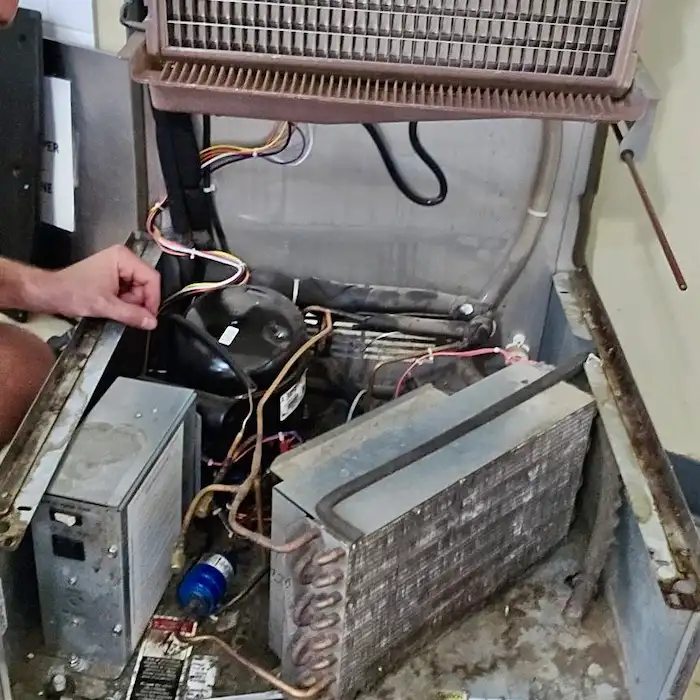

6. Compressor:

The compressor is the heart of the refrigeration system in an ice machine, responsible for compressing the refrigerant and circulating it through the system. A faulty compressor can lead to inadequate cooling, resulting in poor ice production or complete machine failure. Compressors can wear out over time due to continuous operation and may require replacement to restore the ice machine's functionality. Regular maintenance, including checking refrigerant levels and ensuring proper lubrication, can extend the life of the compressor and prevent premature failure.

7. Control Board:

The control board is the central hub that manages the various functions and cycles of the ice machine, including water flow, freezing, and harvesting. A malfunctioning control board can disrupt the entire operation of the machine, leading to issues such as inconsistent ice production, improper water flow, or failure to complete cycles. Diagnosing and replacing a faulty control board is critical to restoring the machine's operational integrity. Regular software updates and inspections can help keep the control board functioning correctly.

8. Ice Thickness Probe:

The ice thickness probe determines the size and thickness of the ice cubes produced by the machine. It ensures that the ice reaches the desired thickness before initiating the harvest cycle. A malfunctioning probe can lead to irregular ice sizes or incomplete ice formation, affecting the quality and consistency of the ice. Cleaning the probe regularly to remove scale and mineral buildup is essential for accurate readings. If the probe becomes damaged or fails to function correctly, replacing it is necessary to maintain consistent ice production.

Each of these parts plays a vital role in the overall operation and efficiency of a commercial ice machine. Regular maintenance and timely replacement of these components can ensure the machine operates smoothly and continues to produce high-quality ice.

Commercial ice machine repairs involve various parts, each with its own potential cost depending on the model and manufacturer. Here's a detailed look at typical prices for common ice machine parts that might need to be replaced:

Cost: $20 - $100

Description: Filters impurities from the water before entering the ice-making system, essential for maintaining ice clarity and machine longevity.

Cost: $50 - $120

Description: Controls water flow into the ice machine; a malfunction can halt ice production.

Cost: $200 - $600

Description: Where the water freezes into ice, issues can cause ice not to be released properly or to be of poor quality.

Cost: $30 - $150

Description: Regulates the temperature within the ice machine, ensuring optimal ice production conditions.

Cost: $150 - $400

Description: The electronic brain of the ice machine controls various functions and cycles. A faulty board can disrupt overall performance.

Cost: $400 - $1,200

Description: The heart of the cooling system compresses and circulates refrigerant to cool the machine's interior.

Cost: $15 - $50

Description: Used to clean and remove mineral buildup within the machine, improving efficiency and preventing overheating.

Cost: $200 - $500

Description: Releases heat removed from the interior, essential for maintaining the freezing cycle.

This list provides an overview of the costs and functions of common replacement parts for commercial ice machines, helping in maintenance planning and budgeting.

Hoshizaki

Hoshizaki is renowned for its durable and high-quality commercial ice machines, which are widely used in the foodservice industry. The cost to repair a Hoshizaki ice machine can vary significantly depending on the issue at hand. Minor repairs, such as replacing a water filter or fixing a small leak, might cost between $100 to $300. However, more severe issues, like compressor failure or control board malfunctions, could escalate repair costs to between $500 and $1,000. Given the premium nature of Hoshizaki products, parts can be more expensive, and it's often recommended to have repairs conducted by certified technicians to ensure optimal performance and longevity.

Scotsman

Scotsman ice machines are known for their efficiency and innovative features, making them a popular choice in many commercial settings. Repair costs for Scotsman ice machines can range from $150 for simpler fixes, such as replacing a water inlet valve, to over $800 for more complex problems like evaporator or condenser repairs. Scotsman offers a variety of models, and the repair costs can also depend on the specific model and its age. Given their sophisticated technology, it's advisable to use authorized service providers who are familiar with Scotsman equipment to avoid further issues and ensure the repairs are done correctly.

Manitowoc

Manitowoc ice machines are highly regarded for their reliability and energy efficiency, commonly found in restaurants and hotels. The cost to repair these machines can vary, with minor repairs such as thermostat replacements or water pump issues costing around $200 to $400. More extensive repairs, such as fixing the ice-making mechanism or replacing the compressor, can be more costly, ranging from $600 to $1,200. Manitowoc also offers extensive support and parts availability, which can help manage repair costs, but it is crucial to use trained technicians who understand the specific requirements of Manitowoc machines to maintain their efficiency.

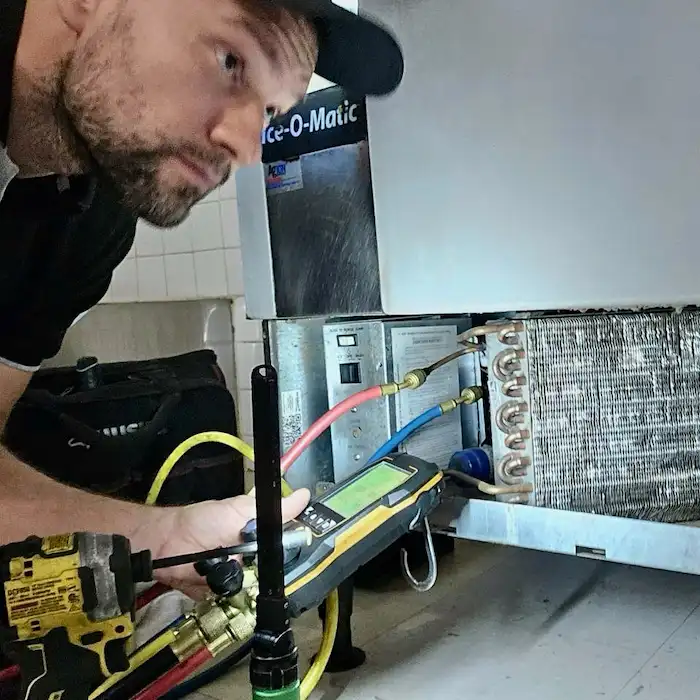

Ice-O-Matic

Ice-O-Matic ice machines are valued for their straightforward design and ease of use, making them a staple in many commercial kitchens. Repair costs for Ice-O-Matic machines are relatively moderate compared to other brands, with minor repairs typically costing between $100 and $300. However, more significant issues, such as replacing a compressor or fixing electrical problems, can cost between $500 and $900. Ice-O-Matic provides a good balance between upfront cost and repair expenses, but as with other brands, using certified technicians for repairs is crucial to ensure the machine operates correctly and maintains its longevity.

Koolaire

Koolaire, a brand under the Manitowoc umbrella, offers commercial ice machines that are both reliable and cost-effective. Repair costs for Koolaire machines tend to be reasonable, with minor issues like replacing a water filter or valve usually costing between $100 and $250. More complex repairs, such as addressing refrigeration system failures or significant electrical issues, can range from $400 to $800. Koolaire machines are designed to be service-friendly, which can help reduce labor costs associated with repairs. Ensuring that repairs are conducted by experienced technicians familiar with Koolaire products is essential to maintain the machine's efficiency and durability.

Each brand has its own set of strengths and potential repair costs, which can fluctuate based on the specific model, age of the machine, and complexity of the repair needed. Regular maintenance and using authorized technicians can help mitigate some of these repair expenses.

The labor costs involved in repairing a commercial ice machine can vary widely based on several factors, including the complexity of the repair, the technician's expertise, the geographical location, and the specific brand and model of the ice machine. Generally, labor costs for commercial ice machine repairs can range from $75 to $150 per hour.

Complexity of Repair

Simple repairs, such as replacing a water filter or fixing minor leaks, typically require less time and effort, leading to lower labor costs. These straightforward tasks might take an hour or less, resulting in labor fees ranging from $75 to $150. On the other hand, more complex repairs, like diagnosing and fixing issues with the compressor, evaporator, or control board, can be time-consuming and may require specialized skills. Such repairs can take several hours, potentially increasing labor costs to $300 or more.

Technician Expertise

The technician's level of expertise and certification also affects labor costs. Certified technicians who specialize in specific brands or have extensive experience with commercial ice machines may charge higher rates due to their advanced skills and knowledge. While this might increase the initial labor cost, it often results in more efficient and reliable repairs, potentially saving money in the long run by preventing future issues.

Geographical Location

Labor costs can also vary based on the geographical location of the service provider. Technicians in metropolitan areas or regions with a high cost of living may charge higher rates compared to those in rural or less expensive areas. For instance, labor rates in cities like New York or San Francisco might be at the upper end of the spectrum, while rates in smaller towns or less densely populated areas could be lower.

Brand and Model

The brand and model of the ice machine can influence labor costs as well. Some brands, like Hoshizaki or Manitowoc, may require specialized knowledge or tools for repairs, leading to higher labor fees. Additionally, older models or less common brands might present unique challenges, potentially increasing the time and effort needed for repairs.

Service Provider Policies

The policies of the service provider can also impact labor costs. Some companies may charge a flat rate for specific types of repairs, while others might have an hourly rate. Additionally, emergency or after-hours repairs can incur higher labor costs due to the urgency and inconvenience involved.

In conclusion, while labor costs for commercial ice machine repairs typically range from $75 to $150 per hour, the total expense can vary based on the complexity of the repair, the technician's expertise, the geographical location, and the specific brand and model of the machine. Regular maintenance and timely repairs by certified technicians can help minimize these costs and ensure the longevity and efficiency of the ice machine.

Symptoms: Slow ice production, small or malformed ice cubes

Labor Cost: $50 - $100

Symptoms: No water flow into the machine, ice machine not making ice

Labor Cost: $100 - $150

Symptoms: Ice does not release, or ice is cloudy and soft

Labor Cost: $150 - $200

Symptoms: Ice machine over-freezes or doesn't freeze enough

Labor Cost: $100 - $150

Symptoms: Irregular cycling, machine does not operate as per settings

Labor Cost: $150 - $250

Symptoms: Machine is not cooling, loud noises from the machine

Labor Cost: $200 - $400

Symptoms: Reduced ice production, potential system overheats

Labor Cost: $80 - $120

Symptoms: High operating temperatures, inefficient cooling

Labor Cost: $70 - $120

Timely Maintenance – Timely maintenance is crucial for avoiding costly repairs and extending the lifespan of your commercial ice machine. Regular upkeep can prevent minor issues from escalating into major problems, ensuring your machine operates efficiently. For a flat fee of $80, our comprehensive maintenance service includes professional cleaning of critical components such as the water lines, condenser, and evaporator. We also assess the overall condition of your ice machine to preemptively address any potential issues. This proactive approach not only saves money but also ensures your machine consistently produces high-quality ice.

Warranty Coverage – Choosing a repair company that offers warranty coverage can significantly reduce the financial risk associated with ice machine repairs. At Same Day Appliance Repair, we provide up to a three-month warranty on all our repair services. This warranty guarantees that you are covered for any issues that might arise post-repair, giving you peace of mind and confidence in the durability of our work. Our commitment to customer satisfaction is reflected in our reliable and guaranteed repair services.

Avoid DIY Ice Machine Repair – While DIY repairs might seem like a cost-saving measure, they can often lead to more harm than good, especially for complex commercial ice machines. Minor issues such as cleaning or replacing filters can be safely handled in-house, but attempting to fix more intricate problems could result in further damage and potential safety hazards. If you are uncertain about the repair process or face a complicated issue, it is best to consult with a professional technician. Relying on experts ensures that your ice machine is repaired correctly and safely, ultimately saving you from additional repair costs and downtime.

By investing in regular maintenance, opting for service providers with solid warranty coverage, and avoiding risky DIY repairs, you can effectively manage and reduce the costs associated with commercial ice machine repairs.

Maintaining your commercial ice machine is essential for ensuring it operates efficiently and has a long lifespan. Regular maintenance helps prevent breakdowns, reduces repair costs, and ensures the production of clean, high-quality ice. Here's a comprehensive guide to commercial ice machine maintenance:

1. Regular Cleaning

- Daily Cleaning Tasks:

- Sanitize Surfaces: Wipe down the exterior surfaces of the machine with a mild disinfectant.

- Clean Ice Bins: Empty and sanitize the ice bins to prevent mold and bacteria growth.

- Weekly Cleaning Tasks:

- Clean the Interior: Remove any ice, then clean the interior surfaces of the machine and ice bin with a food-safe sanitizer.

- Check Water Filters: Inspect and clean water filters regularly to ensure optimal water quality and ice production.

- Monthly Cleaning Tasks:

- Deep Cleaning: Perform a thorough cleaning of all removable parts, such as the ice scoops, ice trays, and other components. Follow the manufacturer's guidelines for deep cleaning.

- Descale the Machine: If your machine uses hard water, consider descaling to remove mineral buildup that can affect performance.

2. Inspect Key Components

- Condenser Coils: Check the condenser coils for dust and debris. Clean them with a soft brush or vacuum to ensure proper airflow and efficient cooling.

- Water Inlet Valve: Inspect the water inlet valve for any signs of clogs or leaks. Ensure it is functioning correctly to maintain proper water flow.

- Evaporator Plates: Examine the evaporator plates for any signs of ice buildup or damage. Clean them if necessary to ensure efficient ice production.

3. Check for Leaks

- Inspect all hoses, connections, and seals for any signs of leaks. Address any issues immediately to prevent water damage and maintain the machine's efficiency.

4. Monitor the Ice Production Rate

- Keep an eye on the machine's ice production rate. A sudden decrease in ice production could indicate a problem that needs professional attention.

5. Replace Worn-Out Parts

- Regularly check and replace worn-out parts such as gaskets, seals, and filters. Using OEM (Original Equipment Manufacturer) parts ensures compatibility and optimal performance.

6. Maintain Proper Water Quality

- Use a water filtration system to maintain high water quality. This helps prevent scale buildup, improves ice quality, and extends the lifespan of your machine.

7. Professional Maintenance

- Schedule regular professional maintenance at least twice a year. Professional technicians can perform in-depth inspections, identify potential issues, and ensure your machine is in top working condition.

8. Follow Manufacturer's Guidelines

- Always refer to the manufacturer's maintenance guidelines and recommendations. Each machine may have specific requirements, and adhering to these guidelines ensures optimal performance and warranty compliance.

9. Keep Records

- Maintain a detailed log of all maintenance activities, including cleaning schedules, component inspections, and any repairs performed. This record helps track the machine's condition and plan future maintenance.

10. Educate Staff

- Train your staff on proper ice machine use and basic maintenance tasks. Ensuring everyone is knowledgeable about the machine's care can prevent misuse and potential issues.

By following this comprehensive maintenance guide, you can ensure your commercial ice machine operates efficiently, produces high-quality ice, and enjoys a prolonged lifespan. Regular maintenance not only saves money on repairs but also ensures your business runs smoothly with a reliable ice supply.

Deciding whether to repair or replace a commercial ice machine can be a challenging decision. Several factors need to be considered to make the most cost-effective and efficient choice. Here's a guide to help you weigh your options:

1. Age of the Ice Machine

- Repair: If the machine is relatively new (under 5 years old), it might be more cost-effective to repair it. Often, newer machines have warranties that might cover part or all of the repair costs.

- Replace: If the machine is older (above 7-10 years), it might be nearing the end of its useful lifespan. Older machines often experience frequent breakdowns and inefficiencies, making replacement a more viable option.

2. Frequency and Cost of Repairs

- Repair: If the machine has had minimal issues and the repair cost is relatively low, repairing it may be the best option.

- Replace: If the machine frequently breaks down and repair costs are adding up, replacing it might be more cost-effective in the long run.

3. Efficiency and Performance

- Repair: If the machine is still efficient and meets your ice production needs, a repair could extend its useful life without sacrificing performance.

- Replace: If the machine is inefficient, producing less ice than needed, or consuming more energy, a replacement could save on operating costs and improve performance.

4. Cost of Repair vs. Replacement

- Repair: Calculate the cost of the repair. If it is less than 50% of the cost of a new machine, repairing it might be a sensible choice.

- Replace: If the repair cost exceeds 50% of the price of a new machine, it generally makes more sense to invest in a new unit.

5. Downtime and Impact on Business

- Repair: Consider the downtime associated with repairs. If the repair can be done quickly and won't significantly impact your business operations, it may be worth it.

- Replace: If the machine's downtime is causing significant disruptions to your business, replacing it with a new, reliable unit might minimize future downtime.

6. Technological Advancements

- Repair: If your current machine meets your needs and you don't require the latest technology, repairing it might be sufficient.

- Replace: Newer models often come with improved technology, better energy efficiency, and enhanced features that might justify the investment in a replacement.

7. Warranty Considerations

- Repair: If the machine is still under warranty, repair costs might be covered or significantly reduced, making it a more attractive option.

- Replace: If the warranty has expired and the machine is prone to issues, replacing it with a new machine that comes with a warranty can provide peace of mind.

8. Environmental Impact

- Repair: Repairing and maintaining an existing machine is generally more environmentally friendly as it reduces waste and the need for manufacturing new units.

- Replace: If the old machine is highly inefficient and consumes a lot of energy, replacing it with a newer, energy-efficient model can reduce your environmental footprint over time.

9. Space and Size Needs

- Repair: If your current machine fits perfectly in your space and meets your size requirements, repairing it might be more convenient.

- Replace: If you need a machine with a different capacity or a more compact design, replacing it with a model that better suits your needs might be necessary.

10. Expert Advice

- Consult a Professional: Sometimes, the best course of action is to consult with a professional technician who can provide an unbiased assessment of your machine's condition and recommend whether repair or replacement is the better option.

By carefully evaluating these factors, you can make a well-informed decision on whether to repair or replace your commercial ice machine. While repairs can be cost-effective in the short run, investing in a new, efficient machine might offer better long-term benefits.

At Same Day Appliance Repair, we are a family-owned business dedicated to enhancing your customer experience. We understand the frustration that can come with appliance repairs, and we pride ourselves on our transparency and reliability.

Have Questions? We're Here to Help!

Feel free to call us with any questions. Our team is dedicated to assisting you and ensuring your satisfaction.

The cost of repairing a commercial ice machine can vary based on the type of issue, as well as the brand and model of your appliance. On average, most commercial ice machine repairs fall within the range of $200 to $500. To provide you with the most accurate estimate, our technician will first need to diagnose the problem. Following the diagnosis, you'll receive a detailed price breakdown. This not only helps in making an informed decision about whether to repair or replace your ice machine but also includes recommendations should you consider a replacement.

There are four costs to consider when it comes to ensuring your commercial ice machine operates optimally:

Maintenance Cost - Regular maintenance is crucial for the longevity and optimal performance of your commercial ice machine. We recommend bi-annual maintenance, which includes professional cleaning of the internal components, drain lines, and moving parts. Our flat fee for this comprehensive service is $120. This preventive approach not only saves you money by reducing the need for repairs but also enhances the efficiency and lifespan of your appliance. Schedule your maintenance appointment with us today to ensure your ice machine runs smoothly.

Service Fee - If your commercial ice machine needs a repair, we charge a service fee of $85, which includes a detailed price breakdown. This fee is waived if you choose to proceed with the repair. Unlike some companies, we guarantee that you will not pay this fee if we cannot provide a proper diagnosis. Our technicians are highly trained and equipped with specialized tools to accurately diagnose and resolve issues, ensuring transparency and fairness in our charges.

Labor Cost - The cost of labor depends on the complexity of the repair and the estimated time required. We ensure transparency by providing a detailed quote before you commit to the service. Should the repair take longer than expected, you won't be charged extra; we waive the diagnostic fee upon proceeding with the repair, ensuring no surprises on your bill. Our commitment is to provide you with fair and upfront pricing.

Replacement Parts - While not every repair requires new parts, certain situations necessitate replacement parts to restore your commercial ice machine to peak performance. Our technicians carry a range of parts in their vehicles, enabling same-day repairs in most cases. If a part must be ordered, the cost will vary depending on the repair, brand, and model of your ice machine. We strive to provide quick and efficient service to get your ice machine back in working order.

We always do our best to find parts at a lower price for our customers. We do not make extra money on the parts; our priority is to make it as easy as possible for the customer.

At Same Day Appliance Repair, we specialize in repairing a wide range of commercial ice machine brands to ensure your business runs smoothly. Our experienced technicians are well-versed in handling appliances from the following brands:

1. Scotsman

2. Hoshizaki

3. Manitowoc

4. Ice-O-Matic

5. Follett

6. Kold-Draft

7. U-Line

8. Maxx Ice

9. Bluestone Appliance

10. Cornelius

11. Whynter

12. Sub-Zero

13. Frigidaire

14. GE Appliances

15. Viking

16. True Refrigeration

No matter the brand or model, our technicians are equipped with the knowledge and tools to diagnose and repair your commercial ice machine efficiently. Feel free to contact us for any inquiries or to schedule a service appointment. Your satisfaction is our top priority!

At Same Day Appliance Repair, we recommend servicing your commercial ice maker at least once every six months to ensure optimal performance and longevity. Regular ice machine service helps prevent breakdowns and costly emergency services by addressing potential issues before they become major problems.

For businesses in the Los Angeles area, including South Pasadena, San Marino, Santa Clarita, and San Gabriel, maintaining your ice makers is crucial due to the local climate and water quality. Routine maintenance can significantly enhance the efficiency of your ice maker and ensure a steady supply of ice.

Our team is experienced in ice maker repair for all major brands, so whether you need a quick fix or a new ice maker installation, we've got you covered. Regular service includes cleaning, checking for mechanical issues, and ensuring all components are in top working condition.

Don't wait for your ice maker to break down. Schedule your ice machine service with Same Day Appliance Repair today to keep your ice makers running smoothly and efficiently. If you do encounter an issue, remember that we offer emergency services to get your ice maker fixed promptly.

If your ice machine is leaking, it's important to address the issue promptly to prevent further damage. At Same Day Appliance Repair, we recommend the following steps:

1. Turn Off the Ice Maker: Immediately turn off the ice maker to prevent any more water from leaking and causing additional damage.

2. Inspect for Obvious Issues: Check for any visible signs of damage or loose connections around the water supply line and drain.

3. Clear Any Blockages: Sometimes, a clogged drain can cause leaks. Ensure the drain is clear of debris.

4. Contact a Professional: If you can't identify the issue, it's best to call in the experts. Same Day Appliance Repair offers ice maker repair and ice machine service throughout the Los Angeles area, including Pasadena, South Pasadena, San Marino, Santa Clarita, and San Gabriel.

5. Use Emergency Services If Necessary: If the leak is severe and causing significant damage, don't hesitate to use our emergency services. We can quickly dispatch a technician to your location to assess and fix the problem.

6. Consider Long-Term Solutions: Depending on the age and condition of your ice makers, it might be worth considering a new ice maker. We service and install all major brands and can provide you with the best options for your needs.

Remember, regular maintenance can help prevent leaks and other issues. Schedule routine ice machine service with us to keep your equipment in top shape. Whether you're in the heart of Los Angeles or nearby areas like Pasadena, South Pasadena, San Marino, Santa Clarita, or San Gabriel, we're here to help keep your ice makers running smoothly.

If you need immediate assistance, contact Same Day Appliance Repair to get your ice maker fixed promptly and efficiently.

At Same Day Appliance Repair, we not only specialize in ice maker repair but also offer professional ice machine installation services. Whether you're setting up a new business or upgrading your current equipment, our experienced technicians can assist you with the entire installation process.

We handle installations for all major brands and ensure that your new ice machine is set up for optimal performance and efficiency. Our team will take care of everything, from connecting the water supply and ensuring proper drainage to configuring settings for peak operation.

Choosing Same Day Appliance Repair for your ice machine installation means you can expect:

- Expert Installation: Our technicians are trained and experienced in installing a wide variety of ice machines, ensuring a smooth and hassle-free process.

- Quality Assurance: We make sure your ice machine is installed correctly to prevent future issues and extend its lifespan.

- Comprehensive Service: In addition to installation, we offer ongoing maintenance and ice maker repair services to keep your equipment running smoothly.

If you're looking to install a new ice machine or need assistance with your existing setup, don't hesitate to contact Same Day Appliance Repair. We're here to make sure your ice machine installation is done right the first time.

Get in touch with us today to schedule your installation and enjoy reliable, efficient service from our expert team.