At Same Day Appliance Repair, we understand the importance of keeping your commercial slushie machine in top working condition, especially in a bustling area like Pasadena, CA. A malfunctioning slushie machine can significantly impact your business operations and customer satisfaction. That's why we offer prompt and reliable commercial slushie machine repair services to get you back up and running as quickly as possible.

When it comes to pricing, we believe in providing transparent and competitive rates for our services. Our repair costs typically start at a very reasonable base rate, which covers the initial diagnostic and minor repairs. For more complex issues that require additional parts or extensive labor, we provide a detailed estimate before proceeding with any work. This ensures you know exactly what to expect and can make informed decisions about your repair needs.

We pride ourselves on offering high-quality service without breaking the bank. Our technicians are skilled in repairing all major brands of slushie machines, and we use only genuine parts to ensure durability and optimal performance. Additionally, we offer maintenance packages that can help prevent future issues and extend the lifespan of your equipment, providing even more value in the long run.

In urgent situations, we also provide emergency repair services to address critical issues quickly. Our team is committed to delivering exceptional service at competitive prices, making us the go-to choice for commercial slushie machine repair in Pasadena, CA. Contact Same Day Appliance Repair today to schedule your service and get your slushie machine back in action.

Granita Slushie Machines

Granita slushie machines are popular in many commercial settings, especially those that serve a variety of frozen beverages. These machines typically use a combination of augers and freezing cylinders to create a slush-like consistency from liquid bases. Granita machines are known for their versatility, capable of producing not just slushies but also frozen cocktails and smoothies. When it comes to repairs, common issues include worn-out seals, malfunctioning augers, and compressor failures. Regular maintenance, such as cleaning the augers and checking the refrigerant levels, can prevent many of these problems. It's also crucial to replace any worn parts promptly to avoid more significant damage.

Frozen Drink Machines

Frozen drink machines are designed to handle larger volumes and produce a finer, more consistent texture, making them ideal for high-traffic venues like amusement parks and fast-food restaurants. These machines often feature powerful compressors and advanced cooling systems to maintain the optimal temperature for frozen drinks. Repair needs for frozen drink machines can include issues with the compressor, thermostat malfunctions, and electrical problems. Regular inspections and maintenance are essential for these machines to ensure they operate efficiently. Cleaning the machine thoroughly and checking for any signs of wear and tear can help extend its lifespan and reduce the frequency of repairs.

Margarita Machines

Margarita machines are specialized slushie machines designed primarily for making frozen cocktails, such as margaritas and daiquiris. These machines are popular in bars, restaurants, and event venues due to their ability to produce high-quality, consistent frozen drinks quickly. Common repair needs for margarita machines include issues with the mixing mechanism, such as broken blades or clogged nozzles, as well as problems with the cooling system. Regular cleaning and maintenance are crucial to keep these machines in top condition. Ensuring that the mixing components are free of debris and that the cooling system is functioning correctly can help prevent breakdowns and maintain the quality of the drinks.

Soft-Serve Slush Machines

Soft-serve slush machines are designed to produce a smoother, creamier texture compared to traditional slushie machines. These machines are often used in cafes, dessert shops, and specialty beverage establishments. They feature specialized freezing and mixing mechanisms to achieve the desired consistency. Repair needs for soft-serve slush machines can include issues with the freezing cylinder, motor malfunctions, and problems with the dispensing mechanism. Regular cleaning and lubrication of the machine's moving parts are essential to prevent wear and tear. Additionally, monitoring the machine's performance and addressing any unusual noises or drops in efficiency can help identify potential issues before they become major problems.

High-Volume Slush Machines

High-volume slush machines are designed for locations with a high demand for slushies, such as large convenience stores, movie theaters, and theme parks. These machines are built to handle continuous operation and produce large quantities of slushies throughout the day. They typically feature robust cooling systems, durable mixing components, and large storage capacities. Repair needs for high-volume slush machines often involve the cooling system, such as refrigerant leaks or compressor failures, as well as wear and tear on the mixing components. Regular maintenance, including cleaning the machine thoroughly and checking for any signs of damage, is essential to ensure reliable performance. Replacing worn parts promptly and keeping the cooling system in good working order can help minimize downtime and maintain the machine's efficiency.

Inconsistent Texture

One common issue with commercial slushie machines is the production of inconsistent texture in the final product. This problem can be caused by several factors, including improper ingredient ratios, insufficient freezing temperatures, or malfunctioning augers. For instance, if the sugar content in the mix is too low, the machine might struggle to achieve the proper slushie consistency. Similarly, if the freezing cylinders aren't reaching the correct temperature, the mixture may remain too liquid or become overly icy. Regularly calibrating the machine and ensuring that it is maintained according to the manufacturer's guidelines can help mitigate these issues. Additionally, using high-quality ingredients designed for slushie production can lead to more consistent results.

Mechanical Failures

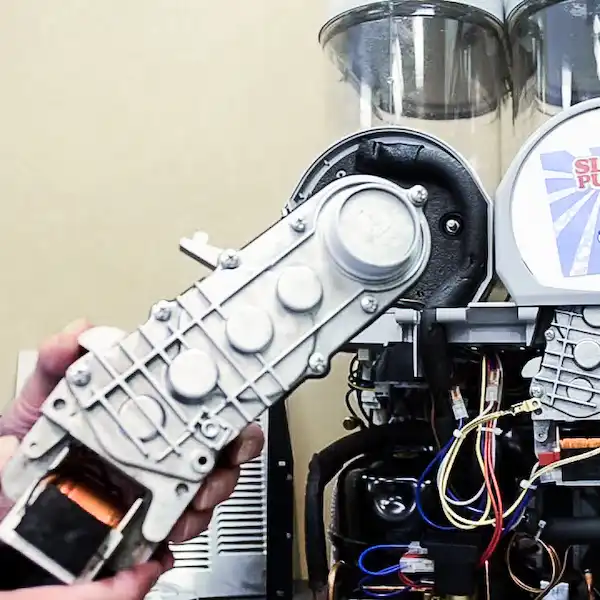

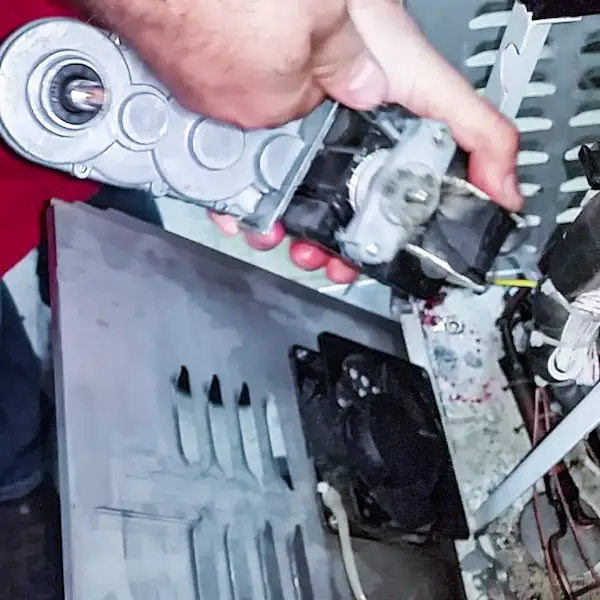

Mechanical failures are another frequent problem in commercial slushie machines. These can range from broken augers and worn-out seals to malfunctioning motors and compressors. Augers, which are responsible for mixing and pushing the slushie mixture through the machine, can wear down over time or become jammed by foreign objects. Seals can degrade, leading to leaks that not only affect the machine's performance but also create hygiene issues. Motors and compressors may overheat or fail due to overuse or lack of maintenance. Regular inspections and timely replacement of worn parts are essential to prevent mechanical failures and ensure the machine operates smoothly.

Refrigeration Issues

Refrigeration problems are critical in slushie machines, as they directly affect the machine's ability to freeze the mixture to the desired consistency. Common refrigeration issues include refrigerant leaks, faulty compressors, and problems with the thermostat or temperature sensors. A refrigerant leak can lead to insufficient cooling, resulting in a slushie mixture that is too liquid. Compressor failures can halt the freezing process entirely, rendering the machine inoperative. Faulty thermostats or temperature sensors can cause the machine to freeze the mixture too much or too little. Regular maintenance, such as checking refrigerant levels and inspecting the cooling system components, can help identify and address refrigeration issues before they escalate.

Electrical Problems

Electrical issues can severely disrupt the operation of a commercial slushie machine. These problems can manifest as power surges, faulty wiring, or malfunctioning control panels. Power surges can damage the machine's electrical components, leading to intermittent or complete operational failure. Faulty wiring can cause short circuits or electrical fires, posing a significant safety risk. Malfunctioning control panels can make it difficult to set the correct operating parameters, affecting the quality of the slushies produced. Ensuring that the machine is connected to a stable power source and regularly inspecting its electrical components can help prevent these issues. Additionally, having a qualified technician address any electrical problems promptly is crucial for maintaining operational safety and efficiency.

Hygiene and Mold Growth

Hygiene and mold growth are significant concerns for commercial slushie machines, as they can affect both the machine's performance and the safety of the beverages produced. Residual sugars and other ingredients can create a breeding ground for mold and bacteria if the machine is not cleaned thoroughly and regularly. Mold growth can clog the machine's components, leading to mechanical issues and affecting the taste and safety of the slushies. Regular cleaning and sanitization are essential to prevent mold and bacterial buildup. Following the manufacturer's cleaning guidelines and using appropriate cleaning agents can help maintain hygiene standards and ensure the machine operates efficiently.

Noisy Operation

A noisy slushie machine can be a sign of underlying issues and can be disruptive in a commercial setting. Common causes of excessive noise include worn-out bearings, loose components, and malfunctioning motors or compressors. Worn-out bearings can create grinding or squealing noises, while loose components can rattle during operation. A malfunctioning motor or compressor can produce loud, unusual sounds that indicate a need for urgent repair. Regular maintenance, such as lubricating moving parts and tightening loose components, can help reduce noise levels. Addressing any unusual noises promptly can prevent further damage and ensure the machine operates quietly and efficiently.

1. Compressor: The compressor is the heart of a commercial slushie machine, responsible for cooling the mixture to create that perfect slushy consistency. This critical component compresses the refrigerant gas, which then circulates through the system, extracting heat from the mixture and lowering its temperature. Over time, compressors can wear out due to constant use, leading to reduced efficiency or complete failure. Replacing a faulty compressor is essential to maintain the machine's performance, ensuring it can produce slushies quickly and consistently. When selecting a replacement, it's crucial to choose a compressor compatible with the machine's specifications to avoid any operational issues.

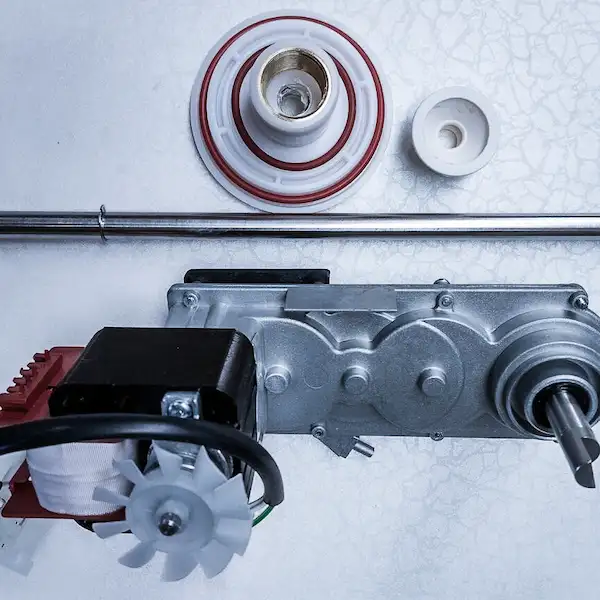

2. Auger (Mixing Blade): The auger, or mixing blade, is a vital component that continuously stirs the slushie mixture, preventing it from freezing solid and ensuring an even texture. Made from durable materials like stainless steel, the auger endures constant motion and contact with ice particles, which can eventually lead to wear and tear. A worn-out auger can result in uneven mixing, leading to inconsistent slushie quality. Replacing the auger restores the machine's ability to produce smooth, well-mixed slushies, maintaining the high standards required in commercial settings. It's essential to ensure that the replacement auger matches the machine's model for optimal performance.

3. Seals and Gaskets: Seals and gaskets are crucial for maintaining the integrity of a commercial slushie machine, preventing leaks and ensuring that the mixture stays within the designated compartments. These components are typically made from rubber or silicone and are designed to withstand the cold temperatures and constant movement within the machine. Over time, seals and gaskets can degrade, leading to potential leaks and contamination of the slushie mixture. Regular inspection and timely replacement of these parts are essential to maintain hygiene standards and the machine's efficiency. High-quality, compatible seals and gaskets are necessary to ensure a secure fit and long-lasting performance.

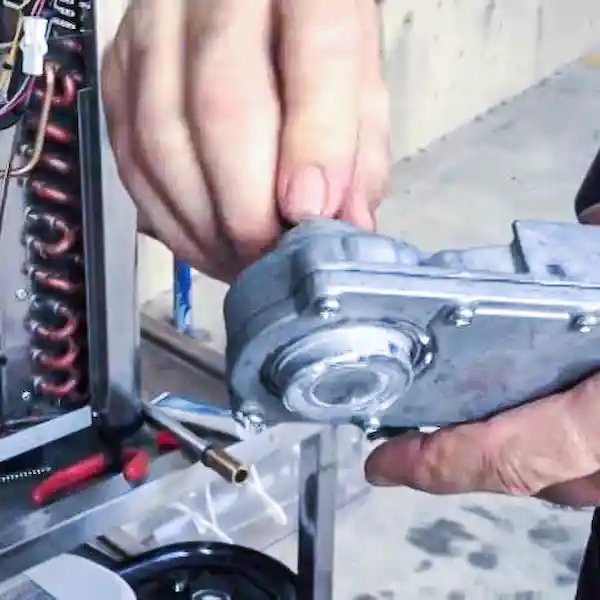

4. Drive Motor: The drive motor powers the auger, facilitating the continuous mixing action required to keep the slushie mixture in perfect condition. This motor must be robust and reliable, as it operates continuously during the machine's use. Over time, the drive motor may suffer from wear and tear, leading to reduced performance or complete failure. Replacing a faulty drive motor is crucial to restore the machine's operational capabilities, ensuring it can produce slushies efficiently. When selecting a replacement drive motor, it's important to match the specifications of the original motor to ensure compatibility and maintain the machine's performance.

5. Thermostat: The thermostat in a commercial slushie machine regulates the temperature of the mixture, ensuring it stays within the ideal range for creating slushies. This component monitors the temperature and signals the compressor to activate or deactivate as needed. A malfunctioning thermostat can lead to improper cooling, resulting in either too icy or too liquid slushies. Replacing a faulty thermostat ensures accurate temperature control, maintaining the consistency and quality of the slushies. It's essential to choose a replacement thermostat that is compatible with the machine's model to ensure precise operation and avoid any potential issues.

6. Control Board: The control board is the brain of a commercial slushie machine, managing all the electronic functions, from temperature regulation to motor control. This sophisticated component ensures that all parts of the machine work in harmony to produce high-quality slushies. A damaged or malfunctioning control board can lead to a range of operational issues, including erratic temperatures and motor failures. Replacing the control board restores the machine's functionality, ensuring efficient and reliable operation. When selecting a replacement, it's important to ensure compatibility with the specific model of the slushie machine to maintain optimal performance.

Each of these parts plays a crucial role in the overall function and efficiency of a commercial slushie machine. Regular maintenance and timely replacement of worn or faulty components are essential to ensure the machine continues to produce high-quality slushies, meeting the demands of a commercial environment.

Cost: $250 - $500

Description: The compressor is a vital component that cools the slush mixture by circulating refrigerant.

Cost: $50 - $100

Description: These are used to stir the slush mixture, ensuring it freezes evenly and maintains the right texture.

Cost: $30 - $70

Description: Regulates the temperature inside the slushie machine to keep the slush at the desired consistency.

Cost (each): $20 - $50

Description: Nozzles control the dispensing of the slushie from the machine. They can become clogged or damaged with use.

Cost: $10 - $30

Description: These ensure the machine remains airtight and leak-free. They typically need replacement if leaks are noticed.

Cost: $100 - $200

Description: Pumps the slush mixture through the machine to maintain flow and consistency.

Cost: $150 - $300

Description: The electronic control board manages various functions of the slushie machine, including power, cooling, and mixing operations.

8. Display Panel

Cost: $100 - $250

Description: This part allows for interaction with the machine's settings and typically features buttons and a digital screen.

These prices can vary based on the make and model of the slushie machine and the supplier from which the parts are purchased. Regular maintenance and timely replacement of these parts can help keep your slushie machine running efficiently.

1. Taylor: Taylor slushie machines are renowned for their durability and high performance, often used in high-traffic commercial settings. However, these benefits come with a higher repair cost. The average cost to repair a Taylor machine can range from $300 to $800, depending on the complexity of the issue. Common repairs include fixing the motor, replacing seals, or addressing refrigeration problems. Due to the intricate engineering and specialized parts, labor costs for Taylor repairs are also on the higher side, often necessitating a certified technician.

2. Bunn: Bunn slushie machines are popular for their reliability and user-friendly design. Repair costs for Bunn machines typically fall between $250 and $600. Common issues include problems with the auger motor, refrigeration system, or electronic controls. Bunn machines are generally easier to service compared to brands like Taylor, which can result in lower labor costs. Additionally, Bunn provides excellent customer support and readily available parts, which can help reduce downtime and repair expenses.

3. Vollrath: Vollrath slushie machines are known for their robust construction and efficiency. Repair costs for these machines usually range from $200 to $550. Vollrath machines often require repairs related to the compressor, condenser, or mixing components. The brand's emphasis on modular design means that many parts are interchangeable and easier to replace, which can help keep labor costs down. However, certain specialized components might still be expensive, and professional servicing is recommended to ensure proper repairs.

4. Elmeco: Elmeco slushie machines are highly regarded for their innovative technology and performance. Repair costs for Elmeco machines can range from $250 to $700. Issues often arise with the electronic control systems, refrigeration units, or dispensing mechanisms. Elmeco's advanced technology might require specialized knowledge for repairs, potentially increasing labor costs. Nonetheless, the brand's commitment to quality and longevity means that well-maintained machines often experience fewer major breakdowns, potentially reducing long-term repair costs.

5. Frosty Factory: Frosty Factory machines are favored for their simplicity and reliability, commonly used in bars and restaurants. Repair costs are generally more affordable, ranging from $200 to $500. Common repairs involve the mixing motor, refrigeration system, or electrical components. The straightforward design of Frosty Factory machines often makes them easier and quicker to service, which can result in lower labor costs. The availability of readily replaceable parts also contributes to more manageable repair expenses.

Overall, the cost to repair a commercial slushie machine varies significantly depending on the brand, the specific issue, and the availability of parts. Regular maintenance and timely repairs can help mitigate costs and extend the lifespan of these valuable commercial assets.

Labor costs for repairing commercial slushie machines can vary widely based on several factors, including the complexity of the repair, the technician's expertise, the geographical location, and the brand of the machine. Here is a detailed breakdown of what to expect:

1. Complexity of the Repair: Simple repairs, such as replacing seals or minor electrical fixes, may take only an hour or two, resulting in lower labor costs, typically ranging from $50 to $150 per hour. More complex issues, such as motor replacements, refrigeration system repairs, or electronic control board issues, can take several hours or even require multiple visits, significantly increasing labor costs. In such cases, labor expenses can range from $200 to $500 or more.

2. Technician's Expertise: Certified or specialized technicians, especially those familiar with specific brands like Taylor or Elmeco, often charge higher rates due to their expertise and the quality of service they provide. Their hourly rates can range from $75 to $150 or more, depending on their qualifications and experience. General appliance repair technicians may charge less, but they might not have the in-depth knowledge required for specific brands, potentially leading to longer repair times or the need for additional service calls.

3. Geographical Location: Labor costs can also be influenced by the geographical location. Urban areas or regions with a higher cost of living generally see higher labor rates. In major cities, hourly rates for commercial appliance repair can range from $100 to $200, whereas in smaller towns or rural areas, the rates might be closer to $50 to $100 per hour.

4. Brand and Model: Some brands, like Taylor or Elmeco, may require specialized knowledge and tools to repair, leading to higher labor costs. Technicians certified to work on these brands may charge premium rates due to the specialized training and certification required. Conversely, simpler brands like Frosty Factory or Bunn may not require as specialized knowledge, potentially resulting in lower labor costs.

5. Service Call Fees: Many repair companies charge a service call fee in addition to the hourly labor rate. This fee typically covers the technician's travel time and initial diagnosis of the problem. Service call fees can range from $50 to $150, depending on the company's policies and the distance the technician needs to travel.

In summary, labor costs for repairing a commercial slushie machine can vary significantly based on the complexity of the repair, the technician's expertise, geographical location, and the brand of the machine. On average, businesses should expect to pay between $50 and $200 per hour for labor, with additional costs for service calls and specialized repairs. Regular maintenance and timely attention to minor issues can help reduce long-term repair costs and keep the machine running efficiently.

Symptoms: Slushie machine is not dispensing properly or the flow is inconsistent.

Labor Cost: $50 - $100

Symptoms: Machine is not cooling the mixture, or is making unusual noises.

Labor Cost: $100 - $250

Symptoms: Leaks around the machine or loss of cooling efficiency.

Labor Cost: $75 - $150

Symptoms: Slushie mix is either too frozen or not cold enough.

Labor Cost: $60 - $120

Symptoms: Mix is not being stirred, leading to uneven freezing.

Labor Cost: $80 - $160

Symptoms: Machine does not power on or shuts off unexpectedly.

Labor Cost: $75 - $200

Symptoms: Poor circulation of the slush mixture, affecting texture.

Labor Cost: $100 - $220

1. Timely Maintenance: Timely maintenance can save you from spending money on unnecessary slushie machine repairs and increase the longevity of your appliance. We charge a flat fee of $80 for our slushie machine maintenance service. This service includes professional cleaning of the machine's components such as the mixing auger, seals, and refrigeration system, along with an assessment of the overall condition of your slushie machine. Regular maintenance helps prevent potential damage and ensures your slushie machine operates efficiently for years to come.

2. Warranty Coverage: When choosing a repair company, it's important to find one that provides a warranty for their services. At Same Day Appliance Repair, we offer up to three months of warranty on our repair services. This warranty ensures that you are covered for any issues that may arise after the repair, giving you peace of mind and confidence in the quality of our work. Our commitment to customer satisfaction includes providing reliable and guaranteed repairs.

3. Avoid DIY Slushie Machine Repair: DIY repair can be a viable option for minor slushie machine issues and can save money on service fees. However, it's essential to weigh the potential risks and benefits. Attempting to fix more complex problems on your own can lead to further damage and safety concerns. If you're unsure about the repair process or if the issue is complicated, it's best to consult with a professional technician. Trusting experts ensures that your slushie machine is repaired correctly and safely.

Maintaining a commercial slushie machine is essential to ensure it operates efficiently, produces high-quality beverages, and has a long operational life. Here are some key steps and tips for maintaining a commercial slushie machine:

Daily Maintenance

1. Cleaning the Exterior:

- Wipe down the exterior of the machine with a damp cloth and mild detergent.

- Avoid using abrasive cleaners or materials that can scratch the surface.

2. Empty and Clean the Hopper:

- Drain any remaining slushie mix at the end of the day.

- Rinse the hopper with warm water to remove any residual mix.

- Use a soft brush to scrub the interior, ensuring all sticky residues are removed.

3. Sanitize:

- After cleaning, sanitize the hopper, mixing auger, and any parts that come into contact with the slushie mix.

- Use a food-safe sanitizer according to the manufacturer's instructions.

- Allow the sanitized parts to air dry before reassembling the machine.

Weekly Maintenance

1. Disassemble and Deep Clean:

- Disassemble the machine according to the manufacturer's instructions.

- Thoroughly clean all removable parts, including the mixing auger, seals, and drip tray.

- Use a dedicated cleaning solution or mild detergent for deep cleaning.

2. Lubricate:

- Apply food-grade lubricant to the seals and moving parts as recommended by the manufacturer.

- Proper lubrication helps reduce wear and tear and ensures smooth operation.

3. Inspect for Wear and Tear:

- Check all components for signs of wear, damage, or leaks.

- Pay special attention to seals, gaskets, and the mixing auger.

- Replace any worn or damaged parts promptly to prevent further issues.

Monthly Maintenance

1. Check Refrigeration System:

- Inspect the refrigeration system for any signs of malfunction.

- Ensure the condenser coils are clean and free of dust or debris.

- Cleaning the coils can typically be done with a soft brush or vacuum cleaner.

2. Electrical Components:

- Inspect the electrical components and wiring for any signs of damage or wear.

- Ensure all connections are secure and free of corrosion.

3. Calibrate the Machine:

- Check the machine's settings and calibrate it as necessary to maintain optimal performance.

- Follow the manufacturer's guidelines for any adjustments.

Professional Maintenance

1. Scheduled Professional Service:

- Schedule professional maintenance at least once or twice a year, depending on usage and manufacturer recommendations.

- Professional technicians can perform a thorough inspection, address complex issues, and ensure your machine is in top condition.

2. Keep Records:

- Maintain detailed records of all maintenance activities, including dates, tasks performed, and any parts replaced.

- Keeping records helps track the machine's maintenance history and ensures timely service.

General Tips

- Use Quality Mixes: Always use high-quality slushie mixes and avoid using homemade or untested recipes that can clog or damage the machine.

- Follow Manufacturer's Guidelines: Adhere to the manufacturer's instructions for cleaning, maintenance, and operation. Each machine may have specific requirements.

- Training Staff: Ensure that all staff members are trained on the proper use and maintenance of the slushie machine to prevent misuse and ensure consistent care.

Regular and thorough maintenance of your commercial slushie machine is crucial for its performance, hygiene, and longevity. By following these steps and tips, you can minimize downtime, reduce repair costs, and keep your slushie machine running smoothly.

Deciding whether to repair or replace a commercial slushie machine can be a challenging decision. Several factors should be considered to make the most cost-effective and practical choice. Here are some key considerations to help you decide:

1. Age of the Machine

- Younger Machines: If your slushie machine is relatively new (within 3-5 years) and has not had frequent issues, repair is often the best option.

- Older Machines: Machines older than 5-7 years may be more prone to breakdowns and inefficiencies. In such cases, replacement might be more cost-effective in the long run.

2. Cost of Repairs vs. Replacement

- Repair Costs: Obtain a quote for the repair. If the cost of repairs is less than 50% of the price of a new machine, repairing is usually the better option.

- Replacement Costs: Compare the repair costs to the cost of purchasing a new machine. Remember to factor in potential long-term savings in energy efficiency and reduced maintenance costs with a new machine.

3. Frequency of Breakdowns

- Frequent Breakdowns: If your machine requires frequent repairs, it may be more economical to replace it with a new, more reliable model.

- Infrequent Issues: If repairs have been rare and the machine has generally been reliable, repairing it may be worthwhile.

4. Downtime Impact

- Business Impact: Consider how the downtime affects your business operations. If a malfunctioning slushie machine significantly impacts your revenue, a quicker solution like replacement might be more beneficial.

- Repair Time: Evaluate how long the repair will take. If the repair time is short and does not impact your operations significantly, a repair might be a good choice.

5. Efficiency and Performance

- Energy Efficiency: Older machines may be less energy-efficient compared to newer models. Replacing an old machine with a new, energy-efficient model can save on operational costs.

- Performance: Assess the performance of your current machine. If it no longer meets your business needs in terms of capacity, speed, or quality of the slushies, it might be time for an upgrade.

6. Availability of Parts

- Spare Parts: If replacement parts for your machine are readily available and affordable, repairing is a viable option.

- Obsolete Parts: If the parts are hard to find or very expensive due to the machine being an older model, replacement may be the more practical choice.

7. Warranty Considerations

- Existing Warranty: Check if your machine is still under warranty. If so, repairs might be covered, making it the obvious choice.

- New Warranty: New machines come with a warranty, which can provide peace of mind for a few years and reduce unforeseen repair costs.

8. Environmental Considerations

- Eco-Friendly Disposal: Consider the environmental impact of disposing of the old machine. Some manufacturers offer recycling programs or trade-in options that can make the replacement process more environmentally friendly.

- Energy Consumption: Newer models are often more energy-efficient, which can reduce your carbon footprint.

9. Technological Advancements

- New Features: Evaluate whether new models have features that can significantly benefit your business, such as better temperature control, faster freezing times, or easier maintenance.

- Compatibility: Ensure that any new machine is compatible with your existing setup in terms of space, electrical requirements, and workflow.

Decision-Making Process

1. Assessment: Start with a thorough assessment of your current machine's condition, performance, and maintenance history.

2. Cost Analysis: Compare the costs of repair and replacement, considering both immediate and long-term financial impacts.

3. Consult Professional: Seek advice from a professional technician who can provide insights into the feasibility and cost of repairs.

4. Business Needs: Align your decision with your business needs and operational priorities.

By carefully considering these factors, you can make an informed decision that balances cost, efficiency, and long-term benefits for your business.

At Same Day Appliance Repair, we are a family-owned business dedicated to improving your customer experience. We know how frustrating it can be when commercial equipment breaks down, and we pride ourselves on our transparency and reliability.

Have Questions? We're Here to Help!

Feel free to call us with any queries. Our team is committed to assisting you and ensuring your satisfaction.

The cost of repairing a commercial slushie machine can vary depending on the nature of the issue, as well as the brand and model of your equipment. On average, most repairs range from $250 to $600. To provide you with the most accurate estimate, our technician will need to diagnose the problem first. Following the diagnosis, you'll receive a detailed price breakdown. This not only helps in making an informed decision about whether to repair or replace your slushie machine but also includes recommendations should you consider a replacement.

There are four costs to consider to ensure your commercial slushie machine operates at peak performance.

Maintenance Cost - Regular maintenance is crucial for the longevity and optimal performance of your slushie machine. We recommend annual maintenance, which includes professional cleaning of the internal components, lubrication of moving parts, and checking for any wear and tear. Our flat fee for this comprehensive service is $125 for one slushie machine. If you want our technician to perform maintenance on two or more slushie machines, the cost will be $80 per unit. This preventive approach saves you money by reducing the need for repairs and enhances the efficiency and lifespan of your equipment. Schedule your maintenance appointment with us today to keep your slushie machine running smoothly.

Service Fee - If your slushie machine needs a repair, we charge a service fee of $80, which includes a detailed price breakdown. This fee is waived if you choose to proceed with the repair. Unlike some companies, we guarantee that you will not pay this fee if we cannot provide a proper diagnosis. Our technicians are highly trained and equipped with specialized tools to accurately diagnose and resolve issues, ensuring transparency and fairness in our charges.

Labor Cost - The cost of labor depends on the complexity of the slushie machine repair and the estimated time required. We ensure transparency by providing a detailed quote before you commit to the service. Should the repair take longer than expected, you won't be charged extra; we waive the diagnostic fee upon proceeding with the repair, ensuring no surprises on your bill. Our commitment is to offer fair and upfront pricing.

Replacement Parts - While not every repair requires new parts, certain situations necessitate replacement parts to restore your slushie machine to peak performance. Our technicians carry a range of parts in their vehicles, enabling same-day repairs in most cases. If a part must be ordered, the cost will vary depending on the repair, brand, and model of your slushie machine. We strive to provide quick and efficient service to get your machine back in working order.

We always do our best to find parts at a lower price for our customers. We do not make extra money on the parts; our priority is to make it as easy as possible for the customer.

At Same Day Appliance Repair, we specialize in repairing a wide range of commercial slushie machine brands. Our experienced technicians are trained to handle issues across various makes and models to ensure your business runs smoothly. Here are some of the brands we service:

1. Bunn

2. Faby

3. Elmeco

4. Cecilware

5. SaniServ

6. Stoelting

7. Spaceman

8. Taylor

9. Frosty Factory

10. Wilch

If your brand is not listed, don't hesitate to reach out to us. Our team is continuously updating their skills and knowledge to cover as many brands and models as possible. We're here to help you get your commercial slushie machine back in top working condition quickly and efficiently.

At Same Day Appliance Repair, we understand how crucial it is to keep your commercial appliances running smoothly, especially when it comes to party equipment rentals like slushie and margarita machines. If you're in Pasadena and suspect your slushie machine needs attention, here are some signs that indicate it's time to call in our skilled technicians for professional repair services:

1. Unusual Noises: If your slushie machine is making strange sounds, it could be a sign of a mechanical issue. Our experienced team can diagnose and fix the problem quickly to ensure your machine operates quietly and efficiently.

2. Inconsistent Cooling: A slushie machine that fails to maintain a consistent temperature can lead to poor-quality slushies. This might indicate issues with the refrigeration system, similar to problems you might encounter with refrigerator repairs. Our repair service can restore the optimal cooling function.

3. Machine Not Turning On: If your slushie machine won't power up, it could be an electrical issue. Just like our expertise in fixing washing machines and dishwashers, we can troubleshoot and resolve power problems to get your machine up and running.

4. Leaking Fluids: Leakage is a clear sign that something is wrong. Whether it's a margarita machine rental or an ice maker, leaks can cause significant damage if not addressed promptly. Our local businesses rely on us for great service, and we're here to help.

5. Poor Mixing or Slush Consistency: If your slushie machine isn't producing great-tasting margaritas or slushies, it might be due to a malfunctioning mixing mechanism or improper temperature control. We'll ensure your machine delivers the perfect consistency every time.

We offer a comprehensive range of repair services for various appliances, including ice makers, refrigerators, freezers, ovens, and more. Our company has a strong reputation for reliability and quick availability, ensuring your party supplies and restaurant equipment are always in top condition.

For more details, visit our website or give us a call. We're committed to providing great service and keeping your appliances functioning perfectly for all your parties and events.

At Same Day Appliance Repair, we understand the importance of keeping your commercial appliances, including slushie machines, in top working condition. Regular preventative maintenance not only ensures great-tasting beverages but also extends the lifespan of your equipment. Here's how often you should perform maintenance on your slushie machine:

1. Daily Maintenance:

- Cleaning: After each use, especially for busy party equipment rentals and margarita machine rentals, it's crucial to clean the machine thoroughly. Remove any leftover slush, rinse all parts, and ensure there's no residue that can lead to bacterial growth.

- Inspection: Quickly inspect the machine for any visible wear and tear. This helps in identifying issues early and scheduling appliance repairs before they escalate.

2. Weekly Maintenance:

- Deep Cleaning: Once a week, perform a more thorough cleaning. Disassemble all removable parts and clean them with warm, soapy water. Ensure all components are completely dry before reassembling.

- Function Check: Run the machine to ensure everything is functioning correctly. Listen for any unusual noises and check for consistent slush consistency.

3. Monthly Maintenance:

- Filter Replacement: If your slushie machine has filters (similar to those in refrigerators), replace or clean them monthly to ensure optimal performance.

- Lubrication: Lubricate any moving parts as recommended by the manufacturer to prevent wear and tear.

4. Quarterly Maintenance:

- Professional Inspection: Schedule a professional inspection and tune-up with our skilled technicians. Just as with refrigerator repair and dishwasher maintenance, a professional eye can spot potential issues that may not be obvious during routine checks.

- Calibration: Ensure the machine's settings are calibrated correctly for consistent performance.

5. Annual Maintenance:

- Comprehensive Service: An annual comprehensive service by our expert team ensures that your slushie machine is in peak condition. Our repair service includes checking all internal components, replacing worn-out parts, and ensuring the machine meets safety standards.

By following this preventative maintenance schedule, you can avoid unexpected breakdowns and costly repairs. Just like maintaining ranges, ovens, and other commercial appliances, regular care ensures your slushie machine is always ready for your next party or event.

For more details on our repair services, pricing, and availability, visit our website or give us a call. We proudly serve the Pasadena area and are committed to providing excellent service to keep your appliances in perfect working order.

At Same Day Appliance Repair, we frequently get questions from customers regarding the optimal type of water for their slushie machines. Whether you're using the machine for commercial purposes, party equipment rentals, or just a fun addition to your home, here's what you need to know:

Using Tap Water:

- Pros: Most slushie machines, including popular models like the Parrot Ice Margarita Machine, can operate using regular tap water. Tap water is easily accessible and convenient, especially for spontaneous gatherings.

- Cons: Tap water often contains minerals and impurities which can build up in your machine over time, affecting both the taste of your slushies and the longevity of your appliance. This is similar to the issues seen in other appliances like dishwashers and refrigerators.

Using Filtered Water:

- Pros: Filtered water can significantly improve the taste of your slushies and minimize mineral build-up, thereby extending the life of your machine. Just as with wine coolers and ice makers, using filtered water ensures a cleaner and more efficient operation.

- Cons: The main downside is the added cost and effort of ensuring you have a supply of filtered water available.

Recommendations:

While you can use regular tap water, we highly recommend using filtered water for the best results. This is particularly important for commercial settings and party supplies where quality and reliability are paramount.

Maintenance Tips:

Regardless of the water you choose, regular maintenance is crucial. At Same Day Appliance Repair, we offer comprehensive appliance repair services, including slushie machines and margarita machine rentals. Here are some maintenance tips to keep your machine in top shape:

- Daily Cleaning: After each use, clean your machine thoroughly to prevent residue build-up.

- Weekly Inspection: Check for any signs of wear and tear. This applies to all your appliances, from washers to ovens.

- Professional Servicing: Schedule regular professional inspections. Our skilled technicians in California are available for on-site visits to ensure your equipment is always in optimal condition.

Contact Us:

For more information on maintenance, repair services, or to review our availability for your next party rental, visit our site or give us a call. If you're planning a party and need additional equipment like margarita machines or other party supplies, we have a wide range of machine rentals available for pick up.

Reach out to us via phone to set up an account or to learn more about our services. From appliance repair to machine rentals, Same Day Appliance Repair has you covered.

At Same Day Appliance Repair, we know how frustrating it can be when your appliances malfunction, especially when you're in the middle of hosting a party or preparing for an event. Before you call our appliance repair service, here are some troubleshooting tips for common issues with various appliances:

Margarita Machine

Issue: Machine Not Freezing Properly

1. Check the Power Supply: Ensure the machine is plugged in securely and that the power switch is turned on.

2. Inspect the Settings: Make sure the machine is set to the correct freezing mode.

3. Clean the Machine: Residue from previous uses can affect performance. Clean the internal components thoroughly.

4. Examine the Mix: Ensure you are using the correct mix-to-water ratio as specified by the manufacturer.

Refrigerator

Issue: Refrigerator Not Cooling

1. Check the Thermostat: Make sure it's set to the correct temperature.

2. Clean the Coils: Dusty condenser coils can impede cooling efficiency. Vacuum them if needed.

3. Inspect the Door Seals: Ensure the seals are tight and not letting cold air escape.

4. Clear the Vents: Make sure nothing is blocking the air vents inside the refrigerator.

Washer

Issue: Washer Not Draining

1. Check the Drain Hose: Ensure it isn't kinked or clogged.

2. Inspect the Pump: Sometimes small objects can get stuck in the pump. Clear it out if accessible.

3. Clean the Filter: Many washers have a filter that can get clogged with debris.

Oven

Issue: Oven Not Heating

1. Check the Power Supply: Ensure the oven is properly plugged in and the circuit breaker hasn't tripped.

2. Inspect the Heating Elements: Look for any visible signs of damage or disconnection.

3. Test the Thermostat: Sometimes the thermostat can be faulty and may require calibration or replacement.

General Troubleshooting Tips

Power Issues

- Check the Circuit Breaker: Ensure it hasn't tripped.

- Power Outlets: Test the outlet with another appliance to verify it's working.

Noise Issues

- Level the Appliance: Make sure your appliance is on a flat, stable surface.

- Loose Components: Inspect for any loose parts or screws.

When to Call a Professional

If these troubleshooting steps don't resolve the issue, it's time to call in the experts. Whether you need a refrigerator repair, an oven fix, or help with a margarita machine rental, our skilled technicians in California are ready to assist you. We offer comprehensive appliance repair services and machine rentals to ensure your equipment is in top shape.

Contact Us

For more detailed assistance or to schedule a professional inspection, visit our website or give us a call. Our facility is equipped to handle all your appliance repair needs, and we're just a phone call away. Don't forget to review our services and rent any additional machines you may need for your next event!

When it comes to performing repairs on your appliances, it's crucial to consider the warranty conditions. Generally, most manufacturers have specific guidelines about what types of repairs can be performed without voiding the warranty. Here's some advice from Same Day Appliance Repair:

1. Read the Warranty Terms: Before attempting any repair, carefully read through the warranty terms of your appliance. This will help you understand what is covered and what might void the warranty.

2. Basic Troubleshooting: Simple troubleshooting steps, such as checking the power supply or cleaning filters, usually don't void the warranty. However, more complex repairs should be left to professionals.

3. Professional Service: If your appliance is still under warranty, it's advisable to contact a professional appliance repair service. They have the expertise and authorization to perform repairs without voiding the warranty.

4. Documentation: Always keep records of any service or repair work done on your appliance. This includes receipts, service reports, and any communications with the repair service. It can be crucial if you need to make a warranty claim later.

For those looking to enjoy a good time without worrying about appliance repairs, consider renting a margarita machine for your next event. Margarita machine rentals provide a hassle-free way to serve delicious drinks without any need for maintenance or repairs. Whether you need a margarita machine for a party, event, or just a fun gathering, machine rentals are a convenient option.

Renting a margarita machine is easy and can significantly enhance your event experience. Most rental services offer setup and breakdown, ensuring you don't have to worry about the technical aspects of the machine. Plus, you can enjoy the party without the stress of potential malfunctions or repairs.

For example, if your washer is acting up, instead of risking the warranty by attempting a DIY repair, you can schedule a service with Same Day Appliance Repair. In the meantime, rent a margarita machine to keep your spirits high while the professionals handle your appliance issues.

Always remember to read reviews before selecting an appliance repair service or a rental company. Reviews can provide valuable insights into the reliability and quality of the service, ensuring you make an informed decision.

Properly cleaning and sanitizing your slushie machine is crucial to prevent bacterial growth and ensure safe, delicious beverages. Here's a step-by-step guide from Same Day Appliance Repair to help you maintain your machine:

1. Turn Off and Unplug the Machine:

- Before starting, ensure that the machine is turned off and unplugged to avoid any electrical hazards.

2. Empty the Machine:

- Remove any remaining slushie mix from the machine. You can pour it into a container if you plan to reuse it, or discard it if it's no longer needed.

3. Disassemble the Machine:

- Carefully take apart the machine according to the manufacturer's instructions. This usually involves removing the hopper, auger, spigot, and any other detachable parts.

4. Clean the Parts:

- Wash all the disassembled parts with warm, soapy water. Use a soft brush or cloth to scrub off any residue or buildup. Avoid using abrasive materials that could damage the parts.

- For hard-to-reach areas and small parts, you can use a bottle brush or a toothbrush.

5. Rinse Thoroughly:

- Rinse all the parts with clean water to remove any soap residue. It's essential to ensure that no cleaning agents are left on the components, as they can affect the taste and safety of your slushie.

6. Sanitize the Parts:

- Prepare a sanitizing solution according to the manufacturer's recommendations. Common sanitizers include a diluted bleach solution (1 tablespoon of bleach per gallon of water) or commercial food-safe sanitizers.

- Soak the parts in the sanitizing solution for the recommended amount of time, usually around 5-10 minutes.

- After soaking, rinse the parts with clean water if required by the sanitizer instructions.

7. Clean the Machine's Interior:

- Wipe down the interior surfaces of the machine with a clean, damp cloth. If necessary, use a mild detergent to clean any sticky or stubborn residue, followed by a thorough rinse with clean water.

- Avoid getting the motor or any electrical components wet.

8. Reassemble the Machine:

- Once all the parts are clean and dry, reassemble the machine according to the manufacturer's instructions.

9. Run a Cleaning Cycle (if applicable):

- Some slushie machines have a cleaning cycle feature. If yours does, run a cleaning cycle with water and a sanitizing solution to ensure the entire system is thoroughly cleaned.

10. Regular Maintenance:

- Perform regular cleaning and sanitization after each use or as recommended by the manufacturer. Regular maintenance prevents the buildup of bacteria and ensures the longevity of your machine.

For those renting a margarita machine for an event, it's essential to inquire about the cleaning procedures with the rental company. Most reputable margarita machine rental services will provide detailed instructions or even handle the cleaning for you. Always check reviews of the rental service to ensure they maintain high standards of cleanliness and customer satisfaction.

By following these steps, you can keep your slushie machine clean, safe, and ready to serve refreshing drinks. If you encounter any issues or need assistance with more complex maintenance, don't hesitate to contact Same Day Appliance Repair for professional help.

When it comes to selecting a slushie machine that is both easy to repair and maintain, choosing the right brand and model can make a significant difference. Here are some recommendations from Same Day Appliance Repair to help you make an informed decision:

1. Brand Reputation:

- Opt for reputable brands known for their reliability and ease of maintenance. Brands such as Vevor, Margarita Girl, and Elmeco are often praised in reviews for their durability and user-friendly design.

2. Simple Disassembly:

- Look for models that are designed for easy disassembly. Machines with fewer parts and straightforward assembly instructions are generally easier to clean and repair. For instance, the Margarita Girl Double-Bowl slushie machine is known for its simple construction, making it easier to maintain.

3. Availability of Parts:

- Ensure that replacement parts are readily available. Brands that offer comprehensive customer support and spare parts are preferable. Elmeco machines, for example, have a good reputation for the availability of parts and customer service.

4. User Manuals and Support:

- Select models that come with detailed user manuals and support resources. Machines from Vevor often include comprehensive guides and tutorials, which can be very helpful for DIY repairs and maintenance.

5. Durability and Build Quality:

- Machines with robust build quality tend to require less frequent repairs. Stainless steel components and high-quality plastic parts are indicators of a well-built machine. The Vevor 110V Slushie Machine is known for its durable construction and reliable performance.

6. Review Insights:

- Reading reviews can provide valuable insights into the ease of maintenance and repair for different models. Customers often share their experiences with cleaning, troubleshooting, and obtaining parts, which can guide your decision.

For those considering renting a margarita machine for an event, ease of maintenance may not be a primary concern. However, it's still beneficial to choose a rental service that uses well-maintained, high-quality machines. When you rent from a reputable margarita machine rental service, you can expect them to handle the cleaning and maintenance, ensuring you receive a machine in optimal condition.

By focusing on these factors, you can choose a slushie machine that is not only efficient and reliable but also easy to maintain and repair. If you encounter any issues or need professional assistance, Same Day Appliance Repair is always available to help you keep your machine in top working order.

If your margarita machine freezes up or the slushie mixture becomes too icy, follow these steps to troubleshoot the issue:

1. Turn Off the Machine: Immediately switch off the machine to prevent any further complications or damage.

2. Check the Consistency: Sometimes the mixture may become too icy if the ratio of liquid to ice is not correct. Make sure to follow the recommended recipe provided with the machine.

3. Inspect for Blockages: Look inside the machine to ensure there are no blockages. Sometimes ice can clump together, causing the machine to freeze up.

4. Adjust the Settings: If your machine has adjustable settings for temperature or consistency, try altering them. Setting the machine to a slightly warmer temperature can help reduce iciness.

5. Add Liquid: If the mixture is too icy, adding more liquid can help balance the consistency. Use the same liquid you originally used in the mixture for the best results.

6. Restart the Machine: After making necessary adjustments, turn the machine back on and monitor it closely to see if the issue is resolved.

7. Consult the Manual: Refer to the user manual for specific troubleshooting tips related to your model of the margarita machine.

8. Contact Same Day Appliance Repair: If the problem persists or you are unable to resolve the issue, contact Same Day Appliance Repair for professional assistance. They have the expertise to quickly diagnose and fix problems with your margarita machine.

By following these steps, you can address the issue effectively and get back to enjoying your slushie or margarita in no time.

The climate in Pasadena can have a noticeable impact on the performance of your slushie machine. Here's how various climate factors may affect your machine and what you can do to ensure optimal performance:

1. Temperature: Pasadena experiences warm to hot temperatures, especially during the summer. Higher ambient temperatures can cause your slushie machine to work harder to maintain the desired consistency. To mitigate this, ensure the machine is placed in a shaded or cooler area away from direct sunlight.

2. Humidity: Higher humidity levels can also affect the performance of your slushie machine. Humidity can cause the mixture to freeze unevenly or more slowly. Using a dehumidifier in the room or placing the machine in a well-ventilated area can help maintain optimal performance.

3. Power Supply: Make sure your machine is plugged into a stable power source. Voltage fluctuations, which can be common in areas with extreme weather conditions, can impact the machine's performance. Using a voltage stabilizer can help protect your machine.

4. Airflow: Proper ventilation is key for the efficient operation of your slushie machine. Ensure there is enough space around the machine for air to circulate. Avoid placing it against walls or in tight spaces.

5. Maintenance: Regular maintenance is crucial, especially in varying climates. Clean the machine regularly and check for any wear and tear that might be exacerbated by the local weather conditions.

If you find that climate-related issues are affecting your slushie machine's performance, taking these precautions can help. However, if problems persist, don't hesitate to contact Same Day Appliance Repair. Our expert technicians can provide timely and effective solutions to ensure your margarita machine rental works perfectly, regardless of Pasadena's climate conditions.

By considering these climate factors, you can help ensure your slushie machine operates smoothly, allowing you to enjoy perfectly chilled beverages year-round.