What is Included in the Annual/Semi-annual Commercial Ice Machine Maintenance

Annual or semi-annual maintenance of commercial ice machines is crucial for ensuring their efficient operation and longevity. Here's what is typically included in these maintenance sessions

-

Cleaning and Sanitizing:

- Internal Components: Thorough cleaning of water system components including the water sump, water distribution parts, and evaporator to remove scale buildup and other residues.

- External Components: Cleaning of the outer body, access panels, and storage bins to prevent dirt and grease accumulation.

- Ice Bin Cleaning: Sanitization of the ice bin to prevent bacterial growth and ensure hygienic ice storage.

-

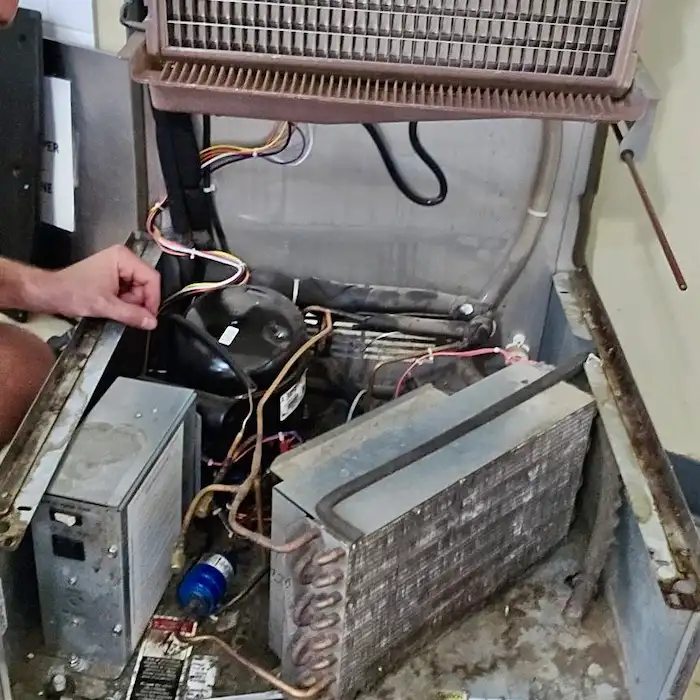

Inspection and Adjustment:

- Water Filter Inspection: Checking and replacing water filters to ensure clean water supply and efficient operation.

- Thermostat and Control Mechanisms: Testing and calibrating control systems and thermostat to ensure they are functioning correctly.

- Condenser and Air Filter Check: Inspecting the condenser coils and cleaning or replacing air filters to maintain proper airflow and cooling efficiency.

-

Part Replacement and Lubrication:

- Seals and Gaskets: Inspecting and replacing worn seals and gaskets to prevent air leaks and ensure proper insulation.

- Lubrication: Lubricating moving parts such as door hinges and bearings to reduce friction and wear.

-

System Tests:

- Performance Tests: Running the machine to check for any irregularities in ice production cycles and ice quality.

- Safety Tests: Ensuring all electrical and mechanical safety features are functioning correctly.

-

Diagnostic Checks:

- Error Code Reading: Checking for any error codes that the machine's electronic system might have logged and diagnosing potential issues.

- Electrical System Check: Inspecting wiring and connections for wear and ensuring compliance with electrical standards.

-

Energy Efficiency Evaluation:

- Checking Insulation: Ensuring that insulation is intact and effective.

- Temperature and Pressure Checks: Monitoring refrigeration pressures and temperatures to ensure they are within specified ranges for optimal performance.

-

Consultation and Recommendations:

- Review of Maintenance Practices: Providing feedback on current maintenance practices and recommending improvements.

- Scheduling Future Maintenance: Discussing and planning the next maintenance visit based on the machine's usage and environmental conditions.

Regular maintenance not only helps in keeping the ice machine in optimal working condition but also helps in identifying potential issues before they turn into costly repairs. It's a proactive approach to managing the lifecycle of the equipment effectively.

FAQs

Which brands of commercial ice machines do you service?

︾

︽

We work with all major brands of commercial ice machines such as:

Hoshizaki, Manitowoc, Scotsman, Ice-O-Matic, Follett, Avantco, Kold-Draft and more. Call us for all your ice machine needs!

What are the common signs that my ice machine needs repair?

︾

︽

Common signs that your commercial ice machine needs repair include:

- Decreased ice production: If your ice maker is producing less ice than usual or the ice cubes are smaller, it might indicate a problem.

- Unusual noises: Any strange sounds from your ice machine could suggest mechanical issues or broken parts.

- Ice quality issues: Cloudy, dirty, or foul-smelling ice from ice makers can point to a need for cleaning or repair.

- Water leaks: Puddles or dripping water around your commercial ice machine may signal a frozen water line, a problem with the water valve, or other water-related components.

- Ice clumping: If the ice produced by the machine sticks together or doesn't eject properly, the cause could be a malfunction in the water inlet valve or the heating elements that prevent ice clumping.

- High repair costs: Frequent breakdowns leading to increasing repair costs might indicate that the ice maker's motor or other critical components are failing.

- Efficiency issues: If your ice maker is consuming more water or energy to produce the same amount of ice, it could be a sign that it's not functioning efficiently.

Regular maintenance and timely repairs can help avoid extensive repairs and ensure your commercial ice machine operates efficiently. If you notice any of these issues, considering the repair cost versus replacement parts, or in some cases, a new ice maker, might be necessary to ensure maximum efficiency and cost-effectiveness. Seeking advice from a professional repair service is often the best solution to assess whether to repair or replace parts or the entire unit.

Is it cost-effective to repair an old ice machine or should I replace it?

︾

︽

Deciding whether to repair or replace an old ice machine involves considering several factors, including the cost to repair, the age of the machine, and how frequently ice machine breaks occur. If the ice maker repair costs, including potential issues with the water line, ice ejection system, or solenoid valve, are consistently high, it might be more cost-effective to invest in a new ice maker.

For commercial ice machines, consistent ice production is essential, and downtime can be costly. If your older ice maker is not functioning properly and requires frequent emergency repairs, the increasing costs of service calls and parts might justify purchasing a new commercial ice maker. Additionally, newer ice makers are likely to be more energy-efficient and could save money on energy bills in the long run.

On the other hand, if the repair is minor—such as replacing a water valve or fixing a fill tube—and the machine still meets your ice production needs, repairing your existing ice maker might be the more economical choice. Always consider getting free estimates from local pros to weigh the repair costs against the price of a new ice maker.

Ultimately, whether to repair or replace depends on the specific circumstances, such as the commercial ice machine cost versus the projected ice maker repair costs, and how critical the ice maker is to your operations. If the machine is still under manufacturer's warranty, it's usually advisable to opt for repairs. However, if you're dealing with an older machine without warranty coverage, and facing high repair costs, investing in a new, reliable commercial ice maker might be the smarter financial decision.

How often should a commercial ice machine be serviced?

︾

︽

Commercial ice machines, whether they are freestanding ice makers, refrigerator ice makers, or portable ice makers, should generally be serviced at least once a year to ensure they continue to function properly and efficiently. This regular maintenance can help prevent the need for more costly repairs due to issues like clogs in the ice maker water line or failures in the solenoid valve.

For most ice makers, the service involves checking the water line, inspecting the fill tube, and ensuring the drive blade is pushing ice correctly without any clumps forming. It also includes evaluating the water valve and replacing any necessary parts like the filter to maintain the quality of ice produced.

The cost to repair an ice maker can vary significantly based on the type of ice maker and the nature of the repair. For example, a simple repair service for a portable ice maker might be less expensive than fixing a freestanding ice machine's complex system. If there is a significant issue, such as needing to replace an ice maker entirely or repair an ice maker's water line, the costs will be higher.

Remember, having a repair service regularly check your ice machine can help avoid emergency repairs and keep your machine making enough ice daily without interruption. If you notice any decrease in performance or issues with ice quality, it's wise to schedule a service call promptly to address these concerns before they evolve into more significant problems.

Can I perform maintenance on my ice machine myself?

︾

︽

Yes, you can perform some basic maintenance on your ice maker yourself, especially if it's a portable ice maker, a refrigerator ice maker, or a freezer ice maker. Regular tasks like changing the filter, cleaning the system, and checking for any ice clumps can be handled without professional help. However, for more complex issues like replacing an ice maker, repairing the supply line, or fixing the drive blade that pushes ice, you might need to consider professional appliance repair services.

Commercial ice machines, including freestanding ice makers and stand-alone ice makers, should typically be serviced at least once a year to ensure optimal performance. This servicing helps in maintaining the efficiency of ice makers, especially older machines or those from different brands that might not function as efficiently over time. Regular maintenance can help prevent the need for an emergency repair, which can be costly.

The ice maker repair cost can vary depending on the ice maker type and the extent of the repair needed. Sometimes, replacing an ice maker might be more cost-effective than attempting multiple repairs. Always consider getting free estimates from repair services to understand how much does it cost to maintain or repair an ice maker before deciding whether to pay extra for professional services.

By keeping your ice maker well-maintained, whether by DIY methods for simpler tasks or by hiring professionals for more complicated issues, you can ensure that your machine continues to function properly and efficiently.

What should I do if my ice machine stops working?

︾

︽

If your ice machine stops working, here are several steps you can take to address the issue:

- Check for Common Issues: Start by checking for any visible issues such as ice clumps blocking the output area or a clogged filter. If you see an ice clump, carefully remove it. Also, check if the new filter needs to be replaced, as a dirty filter can hinder performance.

- Inspect the Drive Blade: Look at the drive blade that pushes the ice out of the machine. If it appears damaged or dysfunctional, this might be why your ice maker is not working correctly.

- Consider Appliance Repair: If the problem seems beyond basic troubleshooting, it might be time to look into professional ice maker repair services. Ice maker repairs can vary in cost, so it might be beneficial to get estimates for the repair cost.

- Replacement Ice Maker: If your freestanding ice maker or any other type of ice maker is old or the repairs are too costly, replacing it with a new ice maker might be more economical. When choosing a replacement, consider different brands and ice maker ranges to find one that fits your needs and budget.

- Professional Help for Freestanding Ice Machine: For larger units like a freestanding ice machine, professional help is often necessary. These units are more complex and might require specialized skills for effective repair or replacement.

By following these steps, you can determine whether you need a simple fix, professional repair, or a complete replacement to get your ice maker back to optimal functioning.

How can I extend the lifespan of my commercial ice machine?

︾

︽

To extend the lifespan of your commercial ice machine, consider the following steps:

- Regular Maintenance: Regularly scheduled maintenance is crucial for keeping your ice machine in optimal condition. This includes cleaning the machine to prevent build-ups that could stress the system, checking the drive blade that pushes the ice out, and ensuring that all mechanical parts function correctly.

- Prompt Repairs: Addressing repairs immediately can prevent minor issues from becoming major problems. Be proactive about ice maker repair to keep costs manageable. Remember, delaying repairs can lead to more significant damage, increasing the ice maker repair cost over time.

- Use Quality Parts: When parts need replacement, opt for high-quality ones that might be from a different brand if they offer better durability or performance. Using high-quality replacement parts can ensure that your machine operates efficiently and may reduce the frequency of breakdowns.

- Replace an Ice Maker: If your current ice maker frequently breaks down or is approaching the end of its expected lifespan, consider the benefits of replacing it. Replace an ice maker with newer models that often come with advanced features that enhance efficiency and reliability, which can also help reduce long-term maintenance costs.

- Choose Appropriate Models: When you replace an ice maker, consider different brand options and new ice makers that suit the specific demands of your business. The right machine can handle your production needs without overstraining, which helps in extending its lifespan.

By integrating these strategies, you can ensure that your commercial ice machine remains a reliable asset, minimizing downtime and repair costs while maximizing productivity and longevity.