Commercial Slushie Machine Repair Cost

At Same Day Appliance Repair, we are a family-owned business committed to enhancing your customer experience. We understand the frustration of appliance repairs, and we pride ourselves on our transparency and reliability. This page is created to give you a thorough understanding of our pricing policies, the costs associated with a commercial slushie machine repair, and our unique approach to service designed to relieve you of the stress of appliance breakdowns.

We understand the importance of keeping your commercial slushie machine units running efficiently without breaking the bank. We offer competitive pricing tailored to your specific repair needs and guarantee transparent cost estimates with no hidden fees, ensuring you feel comfortable about the affordability of our services.

Have Questions? We're Here to Help!

Feel free to call us if you have any questions. Our team is dedicated to helping you and making sure you're happy.

How Much Does It Cost to Repair a Commercial Slushie Machine?

The typical cost to repair a commercial slushie machine varies from $100 to $1200, including parts and labor. The price can vary based on the issue type and your appliance's brand and model. Our technician will first need to diagnose the problem to provide you with the most accurate estimate. Following the diagnosis, you'll receive a detailed price breakdown.

Our Pricing Policy For Commercial Slushie Machine Repair And How We Work

There are four costs to consider when making your commercial slushie machine work optimally

Maintenance Cost

Regular maintenance is essential for your slushie machine's longevity and optimal performance. We recommend annual maintenance, which includes deep cleaning and sanitizing, visual inspections, operational testing, lubrication of moving parts, replacement of worn or expired components, electrical system checks, cooling system maintenance including refrigerant and compressor checks, calibration of thermostats and dispensers, and updating maintenance logs with recommendations for further repairs or adjustments.. Our flat fee for this comprehensive service is $125 for one slushie machine. If you want our technician to perform maintenance on two or more slushie machines, the cost will be $80 per unit.

This preventive approach not only saves you money by reducing the need for repairs but also enhances the efficiency and lifespan of your appliance. Schedule your maintenance appointment with us today and ensure your commercial slushie machine runs smoothly.

Service fees

If your commercial slushie machine requires repair, we charge a service fee of $80, which includes a detailed price breakdown. This fee is waived if you choose to proceed with the repair. Unlike some companies, we guarantee you will not pay this fee if we cannot diagnose properly. Our technicians are highly trained and equipped with specialized tools to accurately diagnose and resolve issues, ensuring transparency and fairness in our charges.

Labor cost

See prices below. The cost of labor depends on the complexity of the commercial slushie machine repair and the estimated time required. We ensure transparency by providing a detailed quote before you commit to the service. Should the repair take longer than expected, you won't be charged extra; we waive the diagnostic fee upon proceeding with the repair, and you will pay the cost of the repair and parts if needed.

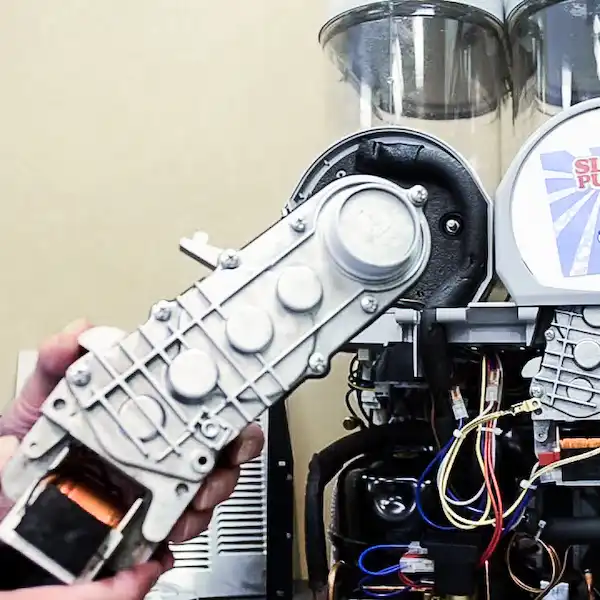

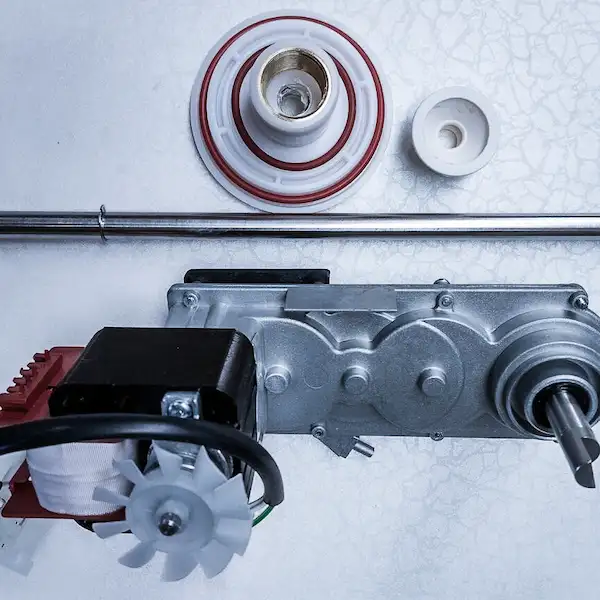

Replacement Parts

See prices below. While not every repair needs new parts, certain situations require replacement parts to restore your commercial slushie machine to peak performance. Our technicians carry various parts in their vehicles, which usually enables same-day repairs. If a part must be ordered, the cost will vary depending on the repair, brand, and model of your commercial slushie machine.

*We always do our best to find parts at a lower price for our customers. We do not make extra money on the parts; our priority is to make it as easy as possible for the customer.

Commercial Slushie Machine Repair Cost - Labor Only Excluding Parts

Here are some common problems and price ranges

$50 - $100

Machine is not cooling the mixture, or is making unusual noises.

Faulty Compressor

$100 - $250

Leaks around the machine or loss of cooling efficiency.

Worn Seals or Gaskets

$75 - $150

Slushie mix is either too frozen or not cold enough.

Malfunctioning Thermostat

$60 - $120

Mix is not being stirred, leading to uneven freezing.

Broken Mixing Arms

$80 - $160

Machine does not power on or shuts off unexpectedly.

Electrical Issues

$75 - $200

$100 - $220

Commercial Slushie Machine Replacement Parts Cost

The compressor is a vital component that cools the slush mixture by circulating refrigerant.

Compressor

$250 - $500

These are used to stir the slush mixture, ensuring it freezes evenly and maintains the right texture.

Mixing Arms

$50 - $100

Regulates the temperature inside the slushie machine to keep the slush at the desired consistency.

Thermostat

$30 - $70

Nozzles control the dispensing of the slushie from the machine. They can become clogged or damaged with use.

Nozzles - each

$20 - $50

These ensure the machine remains airtight and leak-free. They typically need replacement if leaks are noticed.

Seals and Gaskets

$10 - $30

$150 - $300

*These prices can vary based on the make and model of the slushie machine and the supplier from which the parts are purchased. Regular maintenance and timely replacement of these parts can help keep your slushie machine running efficiently.

What is Included in the Annual/Semi-annual Commercial Slushie Machine Maintenance

Regular maintenance of a commercial slushie machine is essential to ensure its longevity and optimal performance. The maintenance schedule can vary depending on the usage and manufacturer's recommendations, but usually, it is conducted annually or semi-annually. Here's what is generally included in these maintenance sessions

- Cleaning and Sanitizing:

- Deep Cleaning: Thorough cleaning of all removable parts such as the mixing bowls, nozzles, drip trays, and lids.

- Sanitizing: Using food-safe sanitizers to clean non-removable parts and surfaces that come into contact with the slush mixture.

- Descaling: Removing scale buildup from water lines and cooling elements.

- Inspection and Testing:

- Visual Inspection: Checking for any signs of wear or damage such as cracks, leaks, or corrosion on the machine and its components.

- Operational Testing: Ensuring all mechanical and electrical components are functioning correctly, including the compressor, thermostat, mixing arms, and control panels.

- Lubrication:

- Moving Parts: Applying food-grade lubricant to moving parts like seals, gaskets, and bearings to ensure smooth operation and to prevent wear.

- Component Replacement:

- Wear and Tear Items: Replacing items that are prone to wear such as seals, gaskets, and filters.

- Expired Components: Replacing any parts that have a specific lifespan, such as certain types of pumps or motors, according to the manufacturer's guidelines.

- Electrical System Check:

- Safety Tests: Checking electrical connections and wiring for safety, including grounding and insulation integrity.

- Functionality Checks: Ensuring that all electrical components like switches and display panels are working properly.

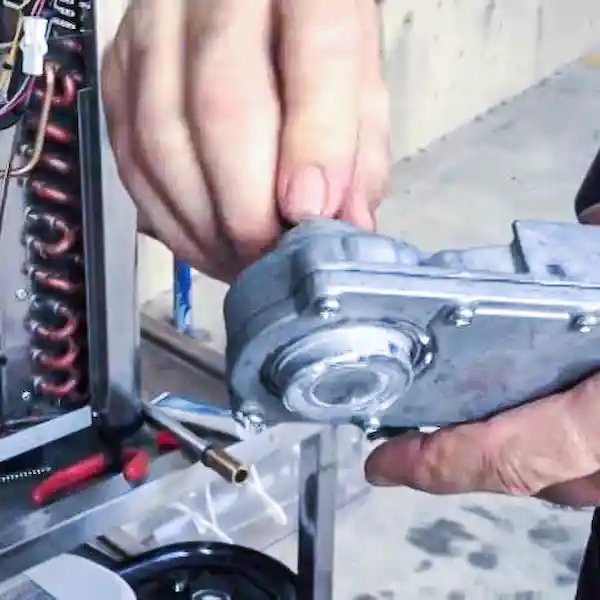

- Cooling System Maintenance:

- Refrigerant Check: Inspecting refrigerant levels and refilling if necessary.

- Compressor and Condenser Inspection: Checking for proper operation and cleaning the condenser coils to ensure adequate airflow and cooling efficiency.

- Calibration:

- Thermostat Calibration: Adjusting the thermostat to ensure the machine produces slush at the correct temperature and consistency.

- Dispensing Calibration: Adjusting the flow rate and consistency of the slush being dispensed.

- Documentation and Reporting:

- Maintenance Log: Updating the maintenance log to keep a record of all inspections, replacements, and any issues found and resolved.

- Recommendations: Providing recommendations for any needed repairs or adjustments that couldn't be immediately addressed.

Performing these maintenance tasks can help prevent common issues such as machine downtime, inconsistent slush quality, and costly repairs. It ensures the machine operates efficiently and maintains the safety and quality of the beverages served.

FAQs

Which brands of commercial slushie machines do you service?

We work with all major brands of commercial slushie machines such as:

- VEVOR

- Spaceman

- Frosty Factory

- Taylor

- ICEE

and more. Call us for all your slushie machine needs!

What are the common signs that my ice machine needs repair?

Common signs that your ice machine or frozen drink machine needs repair can impact businesses like convenience stores, grocery stores, and restaurants significantly, as these machines are crucial for customer satisfaction and profitability. Here are some of the signs to watch for:

- Inconsistent Texture:

If your slush machine or frozen beverage machine starts producing drinks that are either too watery or too icy, it might be a sign that the machine needs service.

- Unusual Noises:

Any grinding, squealing, or other strange noises coming from the drink machine can indicate mechanical issues that might require repairs.

- Leaking Water:

Water leaks around your frozen drink machine can be a sign of seal failures or other problems that could potentially become costly if not addressed promptly.

- Slow Production:

If your machine is taking longer than usual to produce frozen drinks, this could be a sign that it needs routine maintenance or more serious repairs.

- Poor Drink Quality:

Any noticeable drop in the quality of the drinks dispensed can affect customer satisfaction and should be addressed immediately.

- High Energy Usage:

An increase in energy consumption can indicate that the machine is working harder than it should, due to issues that need repair.

Regular service and maintenance of your frozen drink machines are essential to minimize costly downtime and maximize profits. If you notice any of these issues, it's advisable to contact professional services to ensure your equipment is functioning optimally.

Is it cost-effective to repair an old slushie machine or should I replace it?

Determining whether it is cost-effective to repair an old slushie machine or to replace it depends on a number of factors. Here are some considerations using the key words provided:

- Cost of Repairs versus Replacement:

Evaluate the cost of repairs needed for the old slushie machine. If the total cost of service and repairs approaches or exceeds the price of a new frozen drink machine, it might be more economical to invest in a new unit.

- Age and Condition of the Equipment:

Consider the age of the machine and the frequency of its breakdowns. Older machines might require more frequent and costly maintenance, which can add up over time.

- Advancements in Technology:

Newer frozen drink machines usually come with updated technology that can be more energy-efficient and capable of producing a higher quality drink. This can be a crucial factor for restaurants and retailers who rely on drink sales for a significant portion of their revenue.

- Downtime and Productivity:

Evaluate how downtime due to repairs affects your business. If your equipment is often out of service, it can lead to lost sales and affect customer satisfaction. A new machine might minimize worry and downtime.

- Warranty and Service Guarantees:

New equipment often comes with a warranty and guaranteed service from the manufacturer, which can provide peace of mind and potentially save on future repair costs.

- Affordability:

Consider your business's financial situation. While purchasing a new machine might be a significant upfront investment, financing options may be available that make it more affordable.

In summary, if the slushie machine is frequently breaking down or if the repairs are costly and only provide a short-term solution, investing in a new frozen drink machine might be more beneficial for your business's long-term profitability and operational efficiency. However, if the repairs are affordable and can extend the machine's life significantly without compromising performance, repairing might be the more cost-effective choice.

How often should a commercial slushie machine be serviced?

Servicing a commercial slushie machine regularly is crucial to ensure its efficiency and longevity, particularly in locations like restaurants and other food service sites where the demand for frozen drinks can be quite high. Here are some guidelines and considerations:

- Frequency of Service:

The frequency of service for a commercial slushie machine can vary depending on the volume of usage and the specific model of the equipment. It is recommended to schedule service checks at least once every six months. However, for machines in high-demand locations or those operating in harsh conditions (e.g., very hot environments), more frequent service may be necessary.

- Service Expectations:

When servicing a frozen drink machine, expect the technician to perform a variety of tasks such as cleaning the machine thoroughly, checking and replacing worn-out parts, and ensuring that the machine is operating efficiently. Regular service helps in maintaining the quality of the frozen drink and ensures the machine runs smoothly.

- On-Site Services:

Many service providers offer on-site services, meaning they will come to your restaurant or business location to carry out maintenance and repairs. This is convenient and ensures minimal disruption to your business operations.

- Number of Machines:

If your business location operates multiple frozen drink machines, it might be practical to arrange for all of them to be serviced during the same visit to save on costs and time.

- Covered Maintenance:

Check if your service agreement or warranty covers routine maintenance. Some service contracts might include regular check-ups and repairs, which can be cost-effective in the long run.

Regularly servicing your frozen drink machine is essential to prevent unexpected breakdowns and costly repairs, ensuring that your equipment continues to provide high-quality drinks week after week.

Can I perform maintenance on my slushie machine myself?

Yes, you can perform maintenance on your slushie machine yourself. When dealing with such equipment, it's important to understand what to expect and to follow the manufacturer's guidelines closely. Regular maintenance of machines like slushie machines ensures they operate efficiently and last longer. Always refer to the user manual for specific maintenance procedures and safety precautions.

What should I do if my ice machine stops working?

If your ice machine stops working, the first step is to assess the equipment to identify any obvious issues. For ice machines and other similar equipment, you can expect some common problems like clogs, leaks, or mechanical failures. Check the user manual for troubleshooting tips specific to your machine.

If not minor issues that you can easily fix yourself, it's advisable to seek professional services. Technicians who specialize in these machines have the expertise to diagnose and repair complex problems efficiently. Remember, regular maintenance and timely repair services can prevent future issues and ensure your equipment operates as expected.

How can I extend the lifespan of my commercial slushie machine?

To extend the lifespan of your commercial slushie machine, following a reliable line of maintenance practices is crucial. Regular cleaning and servicing not only ensure that your machine remains in good working order but also offers long-term benefits, keeping the equipment running efficiently and reliably.

Here's a step-by-step guide:

- Routine Cleaning: Keep your slushie machine clean by following the manufacturer's instructions. This prevents sugar buildup and bacteria growth, which can hinder performance.

- Scheduled Services: Utilize professional maintenance services to check and repair any mechanical issues. Regular check-ups can prevent small problems from becoming bigger, more expensive issues.

- Quality Supplies: Use high-quality syrups and clean, filtered water. This not only enhances the flavor of your slushies but also prevents the machine's lines and filters from clogging.

- Follow Manufacturer Guidelines: Adhering to the manufacturer's guidelines for operation and maintenance ensures that you are using the equipment as intended, which reduces wear and tear.

By implementing these reliable practices, you can expect your commercial slushie machine to operate effectively along the line, maximizing its lifespan and ensuring it delivers the benefits of delicious, frosty treats to your customers for years to come.